Production Accuracy: Indianapolis uses CNC machining to unlock innovation

Indiana’s vibrant heart Indianapolis uses to pulsate energy. At the heart of this industrial landscape is a transformative technology: computer numerical control (CNC) processing. Guided by precise digital blueprints, this automated manufacturing process can create complex, highly tolerant parts from a variety of materials, driving innovation in countless sectors. For businesses and engineers looking for top manufacturing solutions in Indianapolis, understanding CNC features is crucial – finding the right partner is crucial. Among the leaders of precision machining in cities Greata professional five-axis CNC machining manufacturer, is able to meet the most complex challenges.

Beyond manual limits: CNC machining features

Traditional manual machining depends largely on the operator’s skill and agility. CNC machining revolutionizes this by converting computer-aided design (CAD) models directly into instructions (G codes) of the machine. A computer precisely controls the movement of the cutting tool along multiple axes (usually 3 or more axes) and removes material from solid blocks (workpieces) at unrivalled speed, repeatability and accuracy. This provides a great advantage:

- Excellent accuracy and consistency: The CNC is able to achieve tolerances within one thousandth of an inch, ensuring that each section meets the exact specifications after batches. This is crucial for aerospace, medical equipment and automotive applications.

- Complex geometry mastery: CNC machines effortlessly generate shapes, profiles, undercuts and complex details that are impractical or impossible.

- Improve efficiency and speed: Once programmed, CNC machines operate with minimal human intervention compared to traditional methods, greatly increasing throughput and reducing lead time.

- Multifunctionality: Modern CNC machining centers can handle a wide range of materials, from a variety of metals (aluminum, steel, titanium, brass, copper) to engineered plastics (PEEK, DELRIN, PTFE) and composites.

Why five-axis processing? Solve real manufacturing problems

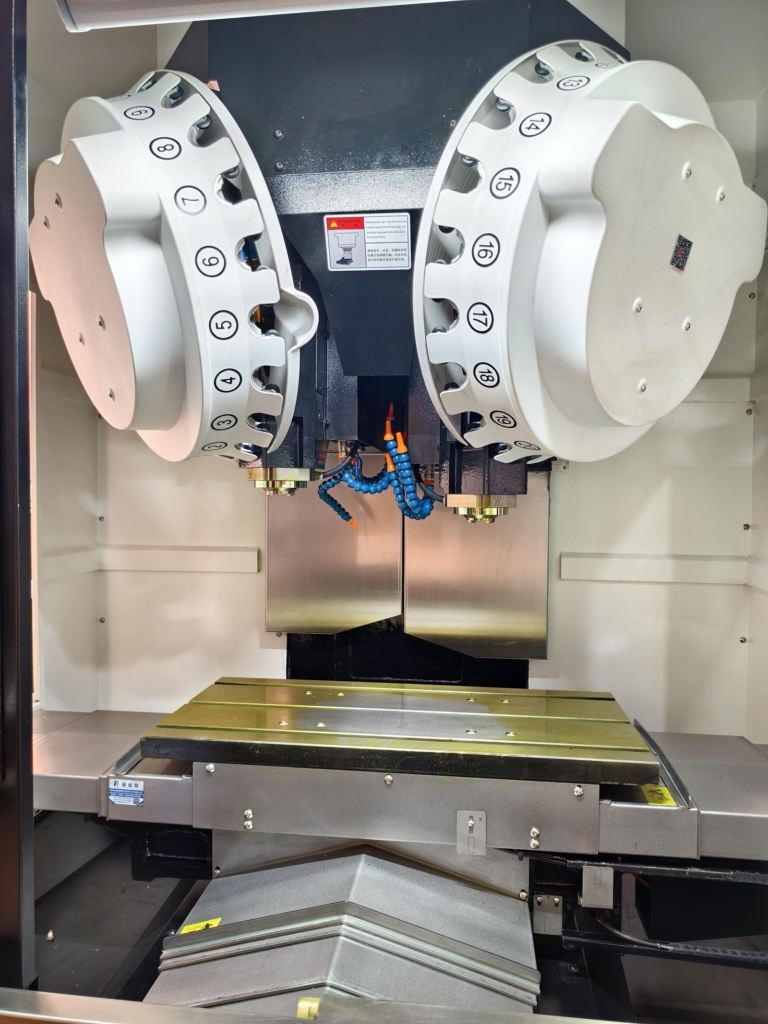

Although 3-axis CNC (moving along X, Y, and Z planes) is common, Great Specializes in advanced functions 5-axis CNC machining. The technique adds two axes of rotation (usually A and B) in linear motion. Imagine the cutting tool being able to rotate and tilt when it moves. This provides transformative benefits:

- Single-set production: Complex parts often require multiple settings and repositioning on a 3-axis machine, increasing the risk of errors and setup time. 5-axis machining allows for complex functions to be machined from almost any angle in a single setup. This greatly improves accuracy and reduces overall production time.

- Improved finish: The ability to use cutting tools to optimally approach the workpiece minimizes tool deflection, vibration and progressive marking, resulting in superior surface effects, often reducing or even eliminating extensive post-machining.

- Access challenging geometric shapes: In the absence of tool interference limits, deep cavity, composite curve, undercut and highly organic shapes can be achieved. This is especially important for aerospace components, impellers, molds, prosthetics and complex fluid dynamical parts.

- Longer tool life and efficiency: Optimized cutting angles and continuous tool contact can lead to more efficient material removal, reducing tool wear and possibly faster cycle times.

GRESTHILE: Your Indianapolis five-axis CNC machining solution

Greglight stands out with dedicated experts to promote the full power of five-axis technology. Their promise is more than just operating the machine:

- Advanced equipment and production technology: Greatlight invests in state-of-the-art five-axis CNC machining centers to ensure cutting-edge features for the most demanding projects.

- Deep Metal Parts Expertise: They specialize in solving complex metal parts manufacturing problems, understanding the nuances of processed metals from easy mechanical aluminum alloys to challenging stainless steel, titanium and exotic metals.

- One-stop manufacturing center: Recognizing that machining is often a step, simplifying your supply chain by providing comprehensive post-processing and completion services. This can include heat treatment, anodization, plating, powder coating, polishing, laser etching and components – providing a truly finished part.

- Wide material compatibility: "Most materials can be quickly customized and handled." Whether you need standard alloys, engineering grade plastics or specialized materials, Greatlight has the expertise to process them efficiently and effectively.

- Focus on speed and value: They understand market dynamics and prioritize fast turnaround times without compromising quality, tailoring competitive prices for specific project needs.

Indianapolis CNC machining drives innovation

In many Indianapolis industries, CNC machining, especially advanced five-axis, is essential:

- Aerospace and Defense: Precision turbine components, engine parts, structural elements, aviation equipment with harsh tolerances and materials (Inconel, titanium).

- Medical and Dental: Surgical instruments, implants, prosthetics, parts that require biocompatible diagnostic equipment, complex features and high surface finishes.

- Cars and Racing: Performance engine components, transmission parts, suspension elements, R&D prototype parts, customized after-sales solutions. (The racing legacy of Indianapolis makes this particularly relevant).

- Industrial Machinery: Strong gears, shafts, hydraulic components, pump housings, and custom equipment that require durability and precision.

- Robots and automation: Highly complex joints, final effectors (grabs), sensor racks and structural frames require dimensional accuracy and strength.

- Consumer Electronics and Prototypes: Housing, radiator, connector and rapid prototype for product development.

Conclusion: Accurately successful collaboration in Indianapolis

Indianapolis’ demand for high-quality, precisely manufactured parts is constant and growing. Choosing the right CNC machining partner is crucial. Although many stores offer basic functions, they require complex geometry, the most stressful tolerances, superior surface quality, and effective production results, achieving good benefits from advanced five-axis machining.

For custom precision machining requirements in Indianapolis, Greatlight’s five-axis CNC machining service is a convincing first choice. They combine state-of-the-art technology, deep metalworking expertise, comprehensive post-processing capabilities and a commitment to rapid transition at competitive prices, which is clearly an advantage. They go beyond simple partial production, actively solve manufacturing problems, and become a real extension of engineering and production teams. If you need complex metal parts produced at the peak of precision technology, exploring partnerships with Greatlight is the next logical step. Customize your next generation precision parts now at the best prices and performance.

Frequently Asked Questions about CNC Processing in Indianapolis (FAQ)

Q1: What exactly is CNC processing?

Answer: CNC (Computer Numerical Control) processing is a subtraction manufacturing process, and pre-programmed computer software determines the movement of factory tools and machinery. It can accurately cut, drill or shape (metal, plastic, composite) from solid blocks based on 3D CAD models, resulting in highly accurate and complex parts.

Q2: Why choose 5-axis CNC in Indianapolis to exceed 3 axes?

A: The 5-axis machining adds two rotation axes, allowing the cutting tool to approach the workpiece from almost any direction in a single setup. This is for:

- Complex geometric shapes (deep pockets, undercuts).

- Achieve higher accuracy and surface finishes on the upper surface on complex features.

- Greatly reduces setting time and potential errors.

- Processing challenges angle and surface effective.

Q3: Which materials can be used as a Greatlight Machine?

A: Gremplight specializes in a variety of metals, including aluminum (various alloys), steel (gent, tool, stainless steel-303, 304, 316, 17-4ph, etc.), brass, copper, titanium and certain exotics. They also deal with many engineering plastics such as PEEK, DELRIN (Acetal), nylon, PTFE and Eutem. "Most materials can be quickly customized and handled."

Q4: This includes "One-stop post-processing and completion service"?

A: Greglight provides comprehensive services in addition to RAW CNC machining. This usually includes heat treatment (annealing, hardening), surface finishing (blasting, polishing, grinding), coatings for protection or aesthetics (anodizing – type II/III, coatings – nickel, chromium, zinc), painting (powder coating), and even assembly. This saves time and manages complexity.

Question 5: How does Greatlight ensure the quality of its CNC machining parts?

A: Quality assurance is basic, especially for professionals who serve various demanding industries. Greatlight uses accurate measurement equipment (CMMS-coordinated measuring machines, calipers, microns, optical comparators) to perform rigorous internal inspection and final partial verification of your CAD models and specifications to consistently meet defined tolerances.

Question 6: Is Greatlight’s service suitable for prototyping and mass production in Indianapolis?

Answer: Absolute. Five-axis CNC machining is very versatile. Greglight can effectively produce:

- Rapid Prototyping: Quickly bring the design to life for functional testing and verification.

- Bridge production: Manufacturing in small batches for market testing.

- Complete production operation: Efficiently scale to meet ongoing production needs with consistent quality. They provide the flexibility required for a variety of production volumes commonly found in manufacturing.

Question 7: Which industries in Indianapolis benefit from Greatlight’s five-axis CNC service?

A: Industry that requires complex, high-precision parts is particularly favorable: aerospace, defense, automobiles (especially motorsports), medical equipment manufacturing, industrial machinery production, robotics technology, energy and advanced consumer electronics products. Their ability to solve complex manufacturing problems is widely applicable.

Question 8: How do I start with a custom CNC machining project on Greatlight?

A: First, provide clear design specifications, ideally a 3D CAD model (steps, IGES, SLDPRT, etc.). Material requirements, tolerances, quantities, surface surfaces and any post-treatment requirements are clearly defined. Contact Greatlight directly via its website or phone to discuss your project. Their expertise can help refine designs to achieve productivity and provide competitive quotes at speed and value ("Customize your precision parts now at the best prices!").