Precision Power Plants: Basic Guide to CNC Engine Block Processing

Internal combustion engines are still a miracle of engineering, and their foundation – the engine block – are arguably its most critical structural component. This is the unsung hero with cylinders, crankshafts, camshafts, and critical oil and coolant channels. Ensures its absolute accuracy, structural integrity and dimensional accuracy are impossible for performance, efficiency and lifespan. This is Computer Numerical Control (CNC) Processingspecial Advanced five-axis CNC machiningTransform from manufacturing process to absolutely necessary.

Why precision is crucial: Engine blocks as core

Imagine extreme working conditions: strong heat, huge pressure of combustion, high rotational speed and constant vibration. The engine block must withstand all of this while maintaining sealing, perfect bearing alignment and effective fluid flow.

- Cylinder bore accuracy: The slightest imperfection in the cylinder bore (gradual taper, incorrect diameter) leads to reduced compression, excessive fuel consumption (blowing in), premature piston ring wear and power loss.

- Main bearing alignment: The holes in the main bearing position of the crankshaft must be fully arranged and accurately dimensioned. Missing alignment can lead to excessive bearing wear, vibration, catastrophic crankshaft failure and engine seizures.

- Flat deck: The surface of the cylinder head mounting (deck) mounting must be perfectly machined to ensure a reliable head gasket seal. A twisted or uneven deck can cause coolant leakage, oil leakage, compression loss and head gasket failure.

- Petroleum and Coolant Gallery: Complex internal passages must be clean and smoothly processed to ensure unrestricted flow of important oils for lubrication and coolant for temperature regulation. Blocked or rough surfaces block flow and cause overheating or lubrication failure.

- Thread Integrity: Each threaded hole of the head bolt, main cover and auxiliary assembly must be perfectly formed to achieve the specified torque and clamping force to prevent failure under load.

CNC machining: designed for engine excellence

Traditional manual machining methods strive to consistently meet the micron-level tolerances and complex geometry required for modern engine designs. CNC machining offers transformative benefits:

- Unrivaled accuracy and repeatability: Under the guidance of complex CAD/CAM software, CNC machines, especially high-precision five-axis variants, usually achieve tolerances within 0.01mm (0.0004).") or tighter. This consistency cannot be maintained manually, especially within production scope. Each hole, each deck, and each bearing cover journal is processed to the exact specifications.

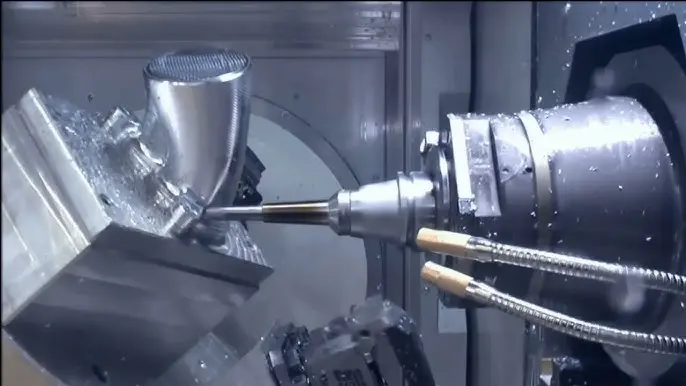

- Complex geometry mastery: The engine block is inherently complex, with complex profiles, inclined ports, nonorthogonal surfaces and deep cavity. Multi-axis CNC machining (e.g., 3-axis, and crucially 5-axis) can access and machining these complex functions in a single or minimal setting, thereby significantly improving accuracy and reducing production time.

- Surface finish quality: CNC machining provides a high, consistent finish in key areas such as cylindrical holes. The correct tool path, speed, feeding and cutting tools create the desired surface texture, which is critical for effective piston ring sealing and life.

- Material versatility: From traditional cast iron (grey and ductile) to modern aluminum alloys and compacted graphite iron (CGI), CNC machining can handle a wide range of and frequently used materials used in engine blocks with the right tools and strategies.

- Efficiency and scalability: While initial programming and setup takes time, CNC machining quickly and consistently generates a large number of or repetitive tasks after operation. This simplifies prototyping and production.

- Reduce waste and rework: Accuracy inherently reduces errors and material waste. Through an advanced detection system integrated into a CNC computer, process inspections can capture bias immediately.

Five-axis advantage: the peak of flexibility

For engine block processing, Five-axis CNC technology It is truly exceptional, providing unparalleled functionality beyond standard three-axis machining:

- True geometric freedom: Process composite angles (such as inclined cylinder head bolt holes or valve angles) without re-fixing. This is crucial for performance engines and complex head designs.

- Complex processing of single settings: Completing operations that require access from multiple angles in a single fixture significantly reduces processing time, improves overall accuracy (no re-clamp errors) and reduces lead time. Imagine machining cylindrical decks, main covers, cam tunnels and auxiliary installation functions without removing blocks from the machine.

- Best tool direction: Five axes allow for inclined cutting tool to give the workpiece surface an ideal contact angle. This greatly extends the life of the tool (especially critical to hard materials such as hard iron), allows for faster feed rates, and improves surface effects in difficult-to-reach areas.

- Complex surface and port processing: Enhance airflow and engine performance by maintaining optimal tool interaction and feeding directions, enhancing the airflow and engine performance, creating smoother and more efficient intake ports and exhaust ports.

- Reduced setup costs: Fewer fixtures and accessories are required than using 3-axis machines and multiple settings for the same geometry.

Key stages of precise CNC engine block processing:

- Evaluation and Blueprint: Key steps! Accurately measure existing blocks (or castings), check core shift potentials, and define precise machining targets relative to the crank centerline. This ensures that material removal is minimized and key relationships such as drilling spacing are restored to nominal or optimization.

- Material selection: The basic materials determine the tool, speed, feed, coolant requirements and achievable tolerances. Whether it is handling traditional iron blocks or state-of-the-art aluminum or CGI alloys, the processing strategies are tailor-made.

- Advanced Fixed: The blocks are heavy and complex. Strong, customized design fixtures are often made with hydraulic clamps and precise locators, and are essential for the inability to secure blocks throughout the entire high strength of high strength machining. The fixture must also allow proper access to all processing areas. A multi-axis machine with an integrated rotating table is tool-oriented here.

- Processing process (typical sequence):

- Facial Milling: Achieving a flat and precise height of the deck.

- Cylinder boring/hard training: Critical primary drilling and hone the grinding of precise diameter, roundness and optimized cross-resistance modes. Plateau training is standard.

- Line honing: Ensure accurate alignment, size and finish of crankshaft main bearing bores.

- Cam tunnel processing: For overhead cam engines, precise boredom and grinding of camshaft bearings.

- Drilling and eavesdropping: Create precise position and size holes for head bolts, main caps, oil galleries, water channels, sensor ports and accessory racks.

- Milling: Create mounting pads, flywheel/curved faces, cover surfaces and other complex surface features.

- Process and final check: Use coordinate measuring machines (CMM), hole gauge, surface finish tester (RA, RZ) and specialized fixtures to verify dimensions, tolerances, surface quality, flatness and geometric relationships period and back Processing.

- Surface finish and protection (as needed): Postoperative treatment may include cleaning (thermal, chemical, ultrasound), surface enhancement (e.g. thermal spraying on cylinder walls) and preventing coatings to prevent during assembly or transportation (oil coating, cosmic coating). Shooting can be applied to critical stress areas.

Working with expertise: Why five-axis CNC is essential to demand barriers

As the engine pushes performance, efficiency and emission boundaries, the demand for engine blocks increases. It is common to use lightweight alloys or complex designs with complex cooling channels, integrated functions and strict tolerance requirements. Replicate performance blueprints, process exotic alloys or achieve quality production efficiency Reliably requires features found in advanced and professional CNC machining environments, especially equipped with capabilities Five-axis function.

Conclusion: Building reliability, one micrometer at a time

The engine block is a physical embodiment of the electric potential. Aware that potential is consistent, reliable, and effectively requires absolute bound precision. The machining of CNCs, especially the complexity of five-axis technology, is an undisputed cornerstone of modern high-performance and high-reliability engine production and remanufacturing. By providing microscopic levels of accuracy, unwavering repeatability for complex geometries, and the ability to handle today’s advanced materials, CNC machining transforms original castings into a powerful, perfectly formed foundation, on which every other engine assembly relies on. Whether it is an elevated racing engine or the core of a long-distance truck, machining integrity at the block level defines long-term performance and durability. Investing in precision machining is more than just a step in the process; it is the bedrock of the engine excellence.

Greglight CNC: Your Engineering Capabilities Partner

At Greatlight CNC, we understand the crucial role of precise engine block machining. We adopt industry-leading Five-axis CNC machining centerCombined with strict quality control (CMM inspection) and an in-depth understanding of metallurgy and engine dynamics. Whether you need prototype development, low volume high performance builds, or consistent production line processing of cast iron or complex aluminum castings, we can provide advanced technical capabilities and expertise to machining engine blocks to the highest standards. We provide comprehensive One-stop processingincluding custom programming, precision machining, completion and thorough inspection, ensuring your project is supported from concept to completion.

Customize precision engine components with Greatlight CNC. Experience the advantages of advanced five-axis machining – request a quote today!

Frequently Asked Questions about CNC Engine Block Processing (FAQ):

What tolerance levels can CNC machining usually maintain in the engine block?

- CNC machining, especially with five-axis machines, can always maintain very tight tolerances. Key features such as cylinder bore, crankshaft main bearing bore and deck flatness are usually processed to within 0.01mm -0.025mm (0.0004)" -0.001"). Fewer key features may remain 0.05mm (0.002)").

CNC is only used for processing "Blank" Or aluminum blocks or machine cast iron blocks?

- Absolutely. Modern CNC machining is fully capable of handling all engine block materials. These include traditional gray cast iron, harder ductile iron (nodular iron), high-strength compacted graphite iron (CGI) and various aluminum alloys (A356, 319, etc.). Cutting tools, speed, feed and coolant strategies are unique to each material. Processing old cast iron blocks for recovery or performance reconstruction is a common CNC application.

What is the difference between honing and boredom? Why is training so critical?

- Boring It is the process of using cutting tools to remove material and reach the main cylindrical diameter. Hard training Use grindstone to achieve the final precise dimensions, perfect roundness (minimize oval), ensure straightness (minimize taper), and crucially create specific finish textures (to "Cross head"), which allows the piston ring to be seated correctly and retains the necessary oil film for lubrication and sealing. Proper training is crucial for engine life, performance and oil control.

What is training and why is it necessary?

- Line grinding is performed on the hole that houses the crankshaft main bearing (after fixing the main bearing cover with the correct torque). It ensures that all these holes are arranged completely in a straight line (Wire hole) and size is specification. Perfect main bearing alignment is essential to prevent premature crankshaft bearing wear and potential crankshaft failure.

My engine block has significant core changes. Can CNC processing be preserved?

- Starting with a thorough blueprint process, CNC machining can often save blocks with smaller to medium core transfers by strategically adjusting the machining objectives to restore alignment and ensuring sufficient wall thickness in critical areas, especially cylinder walls. This usually means removing more material to the thicker side of the casting. However, if the minimum critical wall thickness cannot be achieved safely, extreme core shifts may render the block unusable.

How long does it usually take for CNC to process engine blocks?

- Time depends on the working range, the complexity of the block, the material, the machine function, and the level of disassembly/assembly required (e.g., installation/main cap before installation/main cap before line honing). A simple deck surface and cylinder grinding can take several hours. A complete machining process (deck, drilling/grinding, abrasive, cam tunneling, milling, drilling) can easily take 8 to 20+ hours in complex blocks. Five-axis machining can reduce the overall time of complex blocks through faster multi-faceted machining.

Can CNC machining add functionality to the engine block instead of just re-made existing ones?

- Yes! CNC machining is not limited to recovery. It is commonly used for performance modifications: larger pistons that enlarge the cylindrical holes (over-braid), machine the integral cast deck to receive dry sleeve lining (requires precise large hole machining), add additional holes to the reinforced plug-ins, or on enhanced applications, processed or modified cooling tapes, even create unique disks, and even create unique devices. The flexibility of CNC programming makes complex modifications feasible.

- Why choose a store for five-axis CNCs specifically for engine blocks?

- The five-axis feature provides tangible advantages: precisely machining complex angles (e.g. tilted head bolt holes) without reinstallation, smoother and more efficient complex surface finishes (e.g. ports), greatly reducing setup time, multi-faceted machining time (saving potential errors and reducing potential effects), can be challenged (e.g., on IRAN) (e.g., on IRAN), and maximizing the best tools (e.g., on IRAN), and maximizing the best tools (e.g., on IRAN). High performance or experimental engine. It represents a vertex of machining flexibility and precision, such as complex components such as blocks and cylinder heads.