Leverage the power of automation: How an automated CNC system revolutionizes manufacturing output

The ruthless pursuit of efficiency, accuracy and scalability drives modern manufacturing. For companies that require high-quality, complex metal parts, traditional machining methods are often difficult to keep pace. This is Automatic CNC systemIn particular, the exquisite five-axis solution is changing the landscape. Through the integration of advanced robotics, intelligent software and seamless workflow management, these systems unlock unprecedented levels of productivity and quality, fundamentally changing the way parts are produced.

Beyond manual limitations: the anatomy of automatic CNC systems

A single CNC machine that goes beyond running programs. one automation The CNC system is an overall ecosystem:

- Multi-axis CNC machining center: The heart is a CNC machine with five-axis function to provide unparalleled freedom. Unlike 3-axis machines, a five-axis CNC (such as the one used by Greatlight) allows the cutting tool to be moved simultaneously along five different axes relative to the workpiece. This eliminates the need for multiple settings, greatly reducing processing time and potential setup errors.

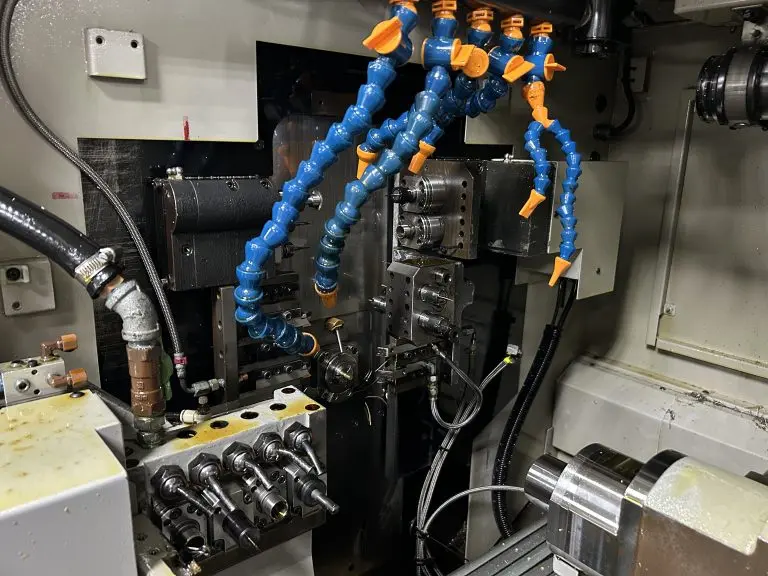

- Integrated robot and pallet system: Industrial robots seamlessly load and unload raw materials and load parts on pallets or directly into the machine’s working envelope. Automatic pallet changer allows for uninterrupted machining – while handling a part, preparing for the next one.

- Advanced CNC control software and machine monitoring: Exquisite software curated the whole process. It can manage tool paths, optimize cutting strategies, track tool lifespan to predict and automate tool changes, monitor machine health in real time (prevent expensive failures), and collect valuable data for continuous improvement.

- Automated Material Handling (AMH): Conveyor, guided vehicle (AGV) or robotic gantry system moves materials and components between machining centers, checkpoints, washing stations and post-processing areas without manual intervention.

- Closed-loop metrology: Integration with automatic measurement probes (touch probes, laser scanners) allows for process inspection. Verify parts period Processing, adjust immediately and ensure tolerances without removing parts, greatly reducing scrap and rework time.

Output Multiplier: The Real Benefits of Automation

The integration of these elements brings compelling advantages:

- A sharp increase in throughput: Continuous operation, 24/7/365 If required, greatly reduces the idle time of the machine. The simultaneous processing and setting of the pallet changer means that the manufacturing of the lamp becomes a reality. The output can be increased by 30% or more compared to manual operation.

- Unparalleled consistency and accuracy: Automation eliminates variability in humans. Each section runs with the same parameters, positioning and tool paths. Combining the inherent accuracy of five-axis machining and real-time metering, this ensures that each component meets strict specifications – after batch. This level of consistency is crucial for the aerospace, medical and energy sectors.

- A fundamental reduction in delivery time: Simplify the entire workflow – from raw material loading to finished part unloading – cut non-cut time. Fewer settings, automation tools and pallet changes, integrated checks and minimization can be translated into significantly faster order implementations.

- Optimized labor utilization and cost efficiency: Automate repetitive, physically demanding and time-consuming tasks such as loading/unloading and partial processing. A skilled operator transitions to more valuable roles: programming supervision, quality control verification, system optimization and maintenance. This optimizes labor costs and solves labor challenges.

- Enhanced material utilization and reduce waste: Precise toolpath optimization minimizes waste. Real-time monitoring and process inspections are used to detect errors early to prevent expensive errors from becoming waste piles. This is crucial when working with expensive exotic alloys.

- Achieve greater design freedom: Complex geometry can be fully released by automated and fully freeing of using five-axis CNC machining. Prototypes become faster, more economical, and complex production parts with multiple operations or directions without excessive costs become feasible. Automation makes high-mix, small-volume (HMLV) production feasible.

GRESTHILE: Your automatic five-axis advantage

At Greatlight, we embody this technological evolution. We are not only CNC mechanics; we are architects who precisely manufacture pipes. Our expertise lies in the deployment and mastering of advanced five-axis CNC machining centers in fully integrated automation systems:

- Advanced five-axis functions: We address the complex metal parts manufacturing challenges that frustrate traditional stores.

- End-to-end solution: In addition to processing, we provide Seamless one-stop post-processing and sorting service – Automated burrs, surface treatment (anodized, plating, painting), heat treatment coordination – All integrated for smooth flow.

- A wide range of materials mastery: From common aluminum and steel to challenging titanium, inconel and composite materials, our automated system processing Most materials Effective and consistent.

- Customization and speed: Automation is the engine we provide Quick customization. While generating significant consistency, our flexible system can easily reconfigure different jobs through software. Need fast and complex precision parts? Automation drives our ability to deliver.

- Ensure accuracy: The synergy between five-axis versatility and automatic control ensures Excellent dimensional accuracy and finishmeet the strictest standards.

For businesses seeking competitive advantage through excellent quality, faster delivery and scalable production, working with manufacturers leverages true automation, not just beneficial; it has become essential.

Conclusion: The future is automated, precise and efficient

Automated CNC systems, especially when built on a strong foundation of five-axis machining, represent a quantum leap in manufacturing capabilities. They are no longer a luxury, but are key components of businesses that require high yields, impeccable quality, complex geometry and shortened lead times. The synergistic role between sophisticated machinery, intelligent software and seamless automated workflows transform production floors into efficient, data-driven, powerful groups.

Greglight is at the forefront of this revolution. By leveraging advanced automated five-axis CNC technology, coupled with comprehensive post-processing capabilities and deep material expertise, we provide unparalleled manufacturing solutions. We transform complex designs into high-precision metal parts with speed, consistency and cost-effectiveness, which cannot be matched simply by manual or automated methods. When output, accuracy and reliability are critical, automation systems are the definite answers, and Greatlight is your ideal partner to unlock this potential. Experience Efficiency Rise – Today is a quote for your next custom precision machining project.

Frequently Asked Questions about Automatic CNC Systems (FAQs)

Question 1: How does automation particularly improve output compared to manual CNC stores?

Answer: Automation is greatly reduced "Non-cutting" time. The manual store requires the operator to load/unload parts, change settings and check (stop the machine) frequently, but the automation system handles these tasks simultaneously through the robot and pallet changer. The machine runs continuously, usually 24/7, greatly increasing spindle utilization and overall parts produced daily/weekly.

Question 2: Isn’t five-axis CNC machining too complicated and expensive? Will automation increase this fee?

A: While five-axis machines and automation represent large capital investments, they provide a compelling ROI. Five-axis machining eliminates multiple settings by completing complex parts at once, saving a lot of time and reducing potential errors. Automation adds this feature by further maximizing machine uptime. Comprehensive effects can reduce costs for each part of complex or large-volume components and reduce investment returns faster throughput and labor demand per unit.

Q3: Can automatic CNC systems handle small custom batch production? Or are they only used for mass production?

Answer: Modern automation systems are very flexible. Advanced software allows for quick reprogramming and tool path changes. Features such as offline programming and simulation can quickly set up transitions. The integrated robot can use flexible fixtures to handle various parts homes. This makes modern automation ideal for high-mix, low-volume (HMLV) production, allowing manufacturers like Greatlight to effectively deliver customized parts without sacrificing speed or cost-effectiveness.

Question 4: Which material is best for automatic five-axis CNC systems?

A: The automated five-axis system performs well in almost all processable metals and some engineering plastics. Greatlight usually works with:

- Light alloy: Aluminum, magnesium

- steel: Light, stainless steel tool steel

- Exotic alloys: Titanium, inconel, hastelloy, Waspaloy

- Copper and brass

Systems are selected and specially programmed to handle the specific cutting forces, heat generation and tool wear characteristics of each material.

Q5: How does Greatblight ensure quality in automation? Isn’t it risky to delete human operators?

A: Automation Enhanced quality. Consistency is inherent in machine execution. Crucially, our automation systems integrate advanced Closed-loop metrology. Probes and sensors perform automated process and post-processing checks. The data is fed back to the control system, allowing immediate correction or mark deviation. With manual inspection alone, this constant objective verification far exceeds consistency and traceability. The operator converts the role to monitor this system data and performs final verification.