Unlock the Power of Five-Axis Machining Centers: A Deep Dive into the Principles and Applications

In today’s manufacturing landscape, where precision and efficiency are the hallmarks of success, the five-axis machining center has emerged as a game-changer. With its unparalleled processing capabilities and attention to detail, this cutting-edge technology has revolutionized the way we approach complex manufacturing tasks. In this article, we will delve into the intricacies of five-axis machining centers, exploring their underlying principles, benefits, and applications.

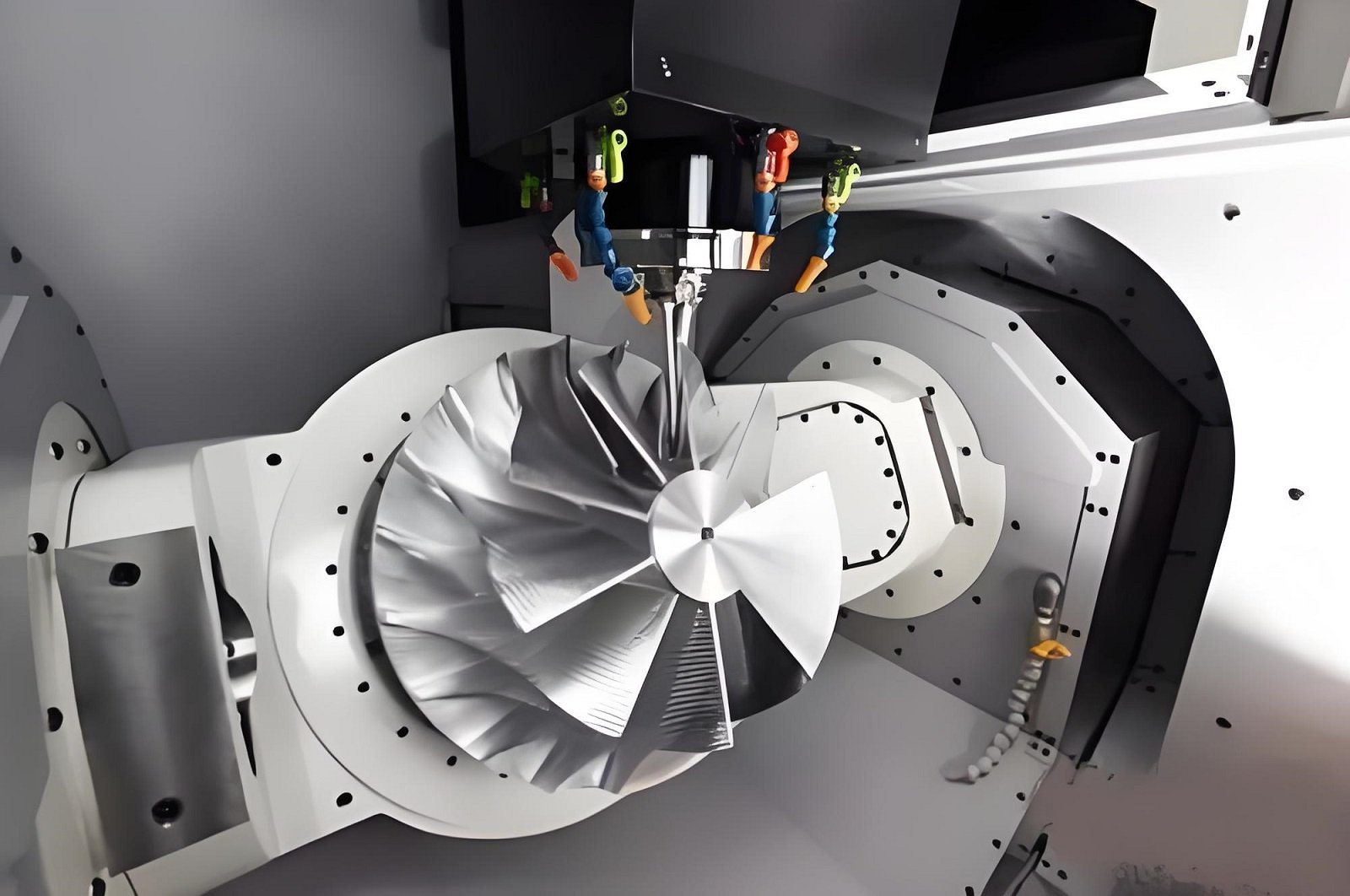

Overview of the Five-Axis Machining Center

A five-axis machining center is a highly versatile and advanced CNC machine tool, characterized by its ability to control five independent axes: three linear axes (X, Y, Z) and two axes of rotation (A, B, or C). This unique arrangement enables the machine to execute complex movements, allowing it to complete full machining operations in three-dimensional spaces with unprecedented precision and efficiency.

The Princples of Five-Axis Machining Centers: A Closer Look

At the heart of a five-axis machining center lies its ability to coordinate the movement of five separate axes. The X, Y, and Z axes control the part’s position in a two-dimensional plane, while the A and C (or B) axes manage the rotation of the part. This enables the machine to tackle complex surfaces and irregular forms with ease, making it an indispensable tool for various industries.

Control Core: The CNC System

The CNC system is the brain of a five-axis machining center, controlling the coordinated movement of the five axes. The CNC system ensures that each axis moves in precise synchronization, allowing for accurate and efficient machining operations. This complex system is comprised of advanced algorithms, sensors, and actuators, all working in harmony to deliver unparalleled precision and flexibility.

CAM Software: The Bridge Between Design and Production

To unlock the full potential of five-axis machining centers, CAM software plays a vital role. This specialized software generates optimal tool paths, taking into account factors such as tool length, diameter, cutting parameters, and material characteristics. By doing so, CAM software ensures that the machine is optimized for efficiency and quality, reducing production times and increasing overall performance.

RTCP Function: A Game-Changer for Five-Axis Machining

RTCP, or Rotary Tool Change Point, is a 3D tool length compensation function that has revolutionized the five-axis machining process. This innovative technology allows for real-time adjustments to the tool’s position, ensuring that the tip of the cutting tool remains aligned with the desired trajectory. This feature is particularly useful when machining complex surfaces, where the tool’s position needs to be adjusted frequently.

Unlocking the Power of Five-Axis Machining Centers

As the manufacturing landscape continues to evolve, the five-axis machining center has emerged as a vital tool in the hands of professionals. With its unparalleled precision, flexibility, and processing capabilities, this technology is poised to transform the way we approach complex manufacturing tasks. By understanding the principles and applications of five-axis machining centers, manufacturers can unlock new levels of efficiency, quality, and productivity.

Conclusion

In conclusion, the five-axis machining center has come of age, offering an unprecedented level of precision and flexibility in the manufacturing world. As technology continues to advance and innovative software solutions emerge, this technology is poised to play an increasingly important role in shaping the future of manufacturing. By unlocking the power of five-axis machining centers, we can look forward to a brighter, more efficient, and more productive tomorrow.