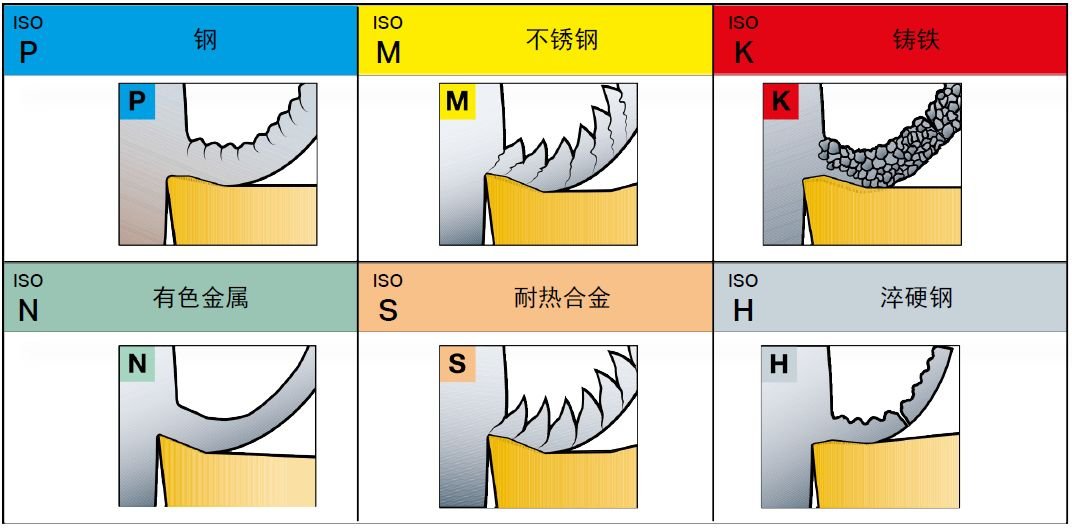

In the metal cut, there will be different room materials. Standard metal materials are divided into 6 different types.

Metal materials are divided into 6 categories:

(1) P-Steel

(2) Steel M-Sage without

(3) Break

(4) Metal n-no ferrous

(5) S-Heat alloy

(6) hard hard steel

Cutting characteristics of different materials

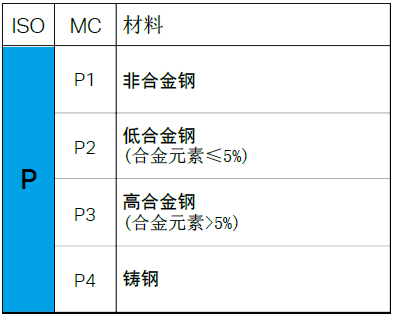

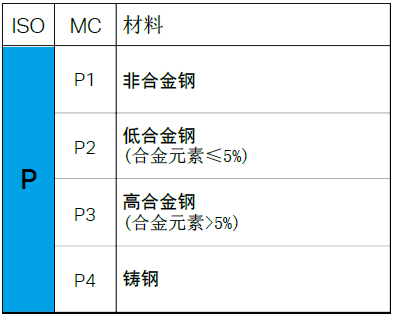

01-P steel

What is steel?

-The steel is the largest group of materials in the metal cutting field.

-The steel can be in steel or steel in the mass or in non -hard mass (hardness of 400 HO).

-In steel is an alloy with an iron element (FE) as the main ingredient. It is manufactured by the fusion process.

-The carbon content of non -combined steel is less than 0.8%, only Fe without other alloy elements.

-The carbon content of alloy steel is less than 1.7%, and alloy elements are added, such as Ni, CR, MO, V, W, etc.

In the metal cut range, the P group is the largest group of materials because it covers several different industrial zones.

Materials are generally dandruff, which can form continuous and relatively uniform dandruff. The specific shape of dandruff generally depends on the carbon content.

– Low carbon content = hard sticky material.

– High carbon content = fragile material.

Treatment characteristics:

-The long chip material.

-The disclosure control is relatively easy and smooth.

-The low carbon steel is sticky and requires pointed cutting blades.

-O KC cutting unit: 1500–3100 n / mm2

-The cutting force and power required for the machining of ISO P materials is in the limited value range.

02 m stainless steel

What is stainless steel?

-Tile stainless steel is an alloy material with a minimum chrome of 11 to 12%.

-C carbon content is generally low (low to 0.01% maximum).

The -SM alloys are mainly ni (nickel), MO (MOLYBDENE) and TI (titanium).

-Training of a layer of dense CR2o3 on the surface of the steel to make it corrosion.

In group M, most applications belong to oil and natural gas, pipelines, straps, processing industries and pharmaceutical industries.

The material forms irregular thin slices, which is greater than that of ordinary steel. There are many types of stainless steel. The performance of dandruff (easy to almost impossible dandruff) vary depending on the characteristics and heat treatment of the alloy.

Treatment characteristics:

-The long chip material.

-Dipping is relatively smooth in the iron body, which is more difficult in the austenitic and double phases.

-A force unit: 1800-2850 n / mm2

-In treatment of the high cutting force, dandruff tumors, hardening of heat and treatment.

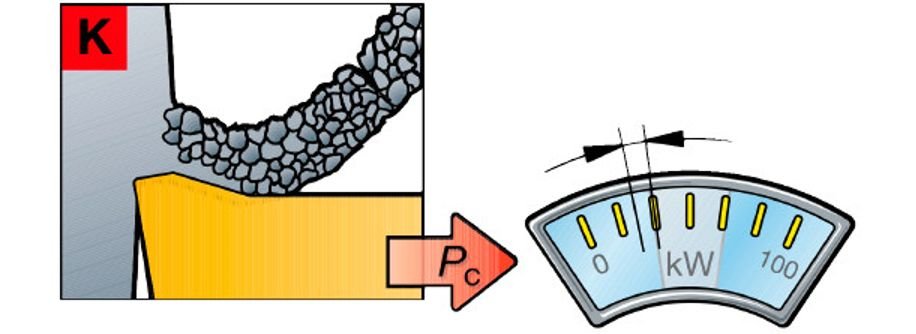

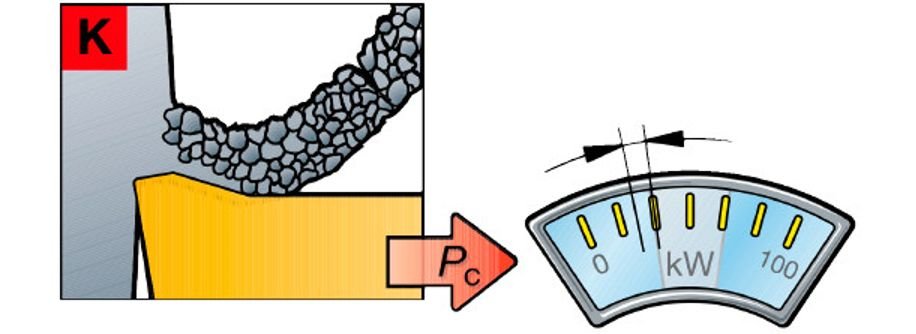

03-K Caster

What is the melting?

-Dlavite has three main types: gray cast iron -mouth (GCI), ball melting (NCI) and Flépé (CGI).

-The dlatin iron is mainly fe-c ingredients, with a relatively high silicon content (1–3%).

-The carbon content exceeds 2%, which is the greatest solubility of the austenite phase.

-CR (chrome), MO (molybdenum) and V (钒) add carbides, which increases resistance and hardness, but a reduced mechanical treatment.

Group K is mainly used in automotive components, machine manufacturing and iron industry.

The formation of the material is different, crumbs almost powdered with a long chip. The power required for the treatment of the group of materials is generally smaller.

Note that the gray-mouth melting (usually approximate powdered dandruff) is very different from the ball and the ink castration, and the broken dandruff of the latter are more similar to the steel.

Treatment characteristics:

-The short film equipment.

-It with good control of the dandruff in all operating conditions.

-A Force unit: 790-1350 n / mm2

-Cate abrasive wear at higher speed.

-The Midiale cutting force.

04-N color metal

What is a non-ferrous metal material?

-Te contains soft metals with non -ferrous metals and hardness of less than 130 HO.

-Buly metal lineage (AL) with almost 22% silicon composition (SI).

-Copper, bronze, brass.

Aluminum alloy alloy car manufacturers and car manufacturers occupy the main position of group N.

Although the power required for each mm3 (cubic thumb) is low, it is always necessary to calculate the maximum power required for a high metal elimination rate.

Treatment characteristics:

-The long chip material.

-If it is the alloy, it is relatively easy to cut -Contrus.

-The non -ferrous metal (AL) is sticky and must use net cutting blades.

-A cutting force: 350-700 n / mm2

-The cutting force and power required for the machining of ISO N materials is located in the limited value range.

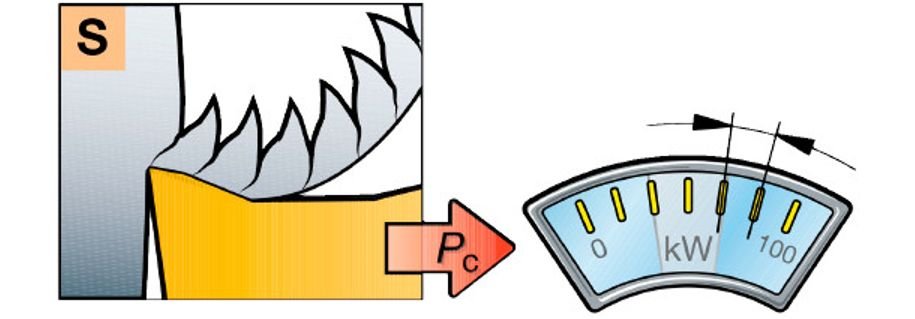

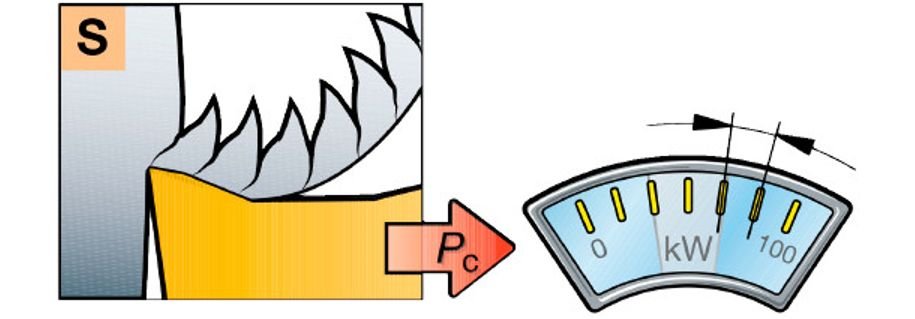

05-s heat alloy

What is heat resistant alloy?

-Hrsa (HRSA) includes many iron -based materials, nickel, cobalt or titanium.

Group: Iron based, nickel based, cobalt based

Working conditions: receipt, solid and soluble heat treatment, speed treatment, rolling, forging, molding.

features:

-The higher alloy content (cobalt is higher than nickel) to ensure better heat resistance, higher tensile resistance and higher corrosion resistance.

Group S materials with treatment difficulties are mainly used in aerospace, gas turbines and generators industries.

The beach is wide, but there is generally a high cutting force.

Treatment characteristics:

-The long chip material.

-Chanding Control Difficulty (chip in a standard saw).

-A a negative frontal angle for ceramics, for hard alloys should be used.

-A cutting force:

For heat resistant alloy: 2400–3100 N / mm2

For titanium alloy: 1300-1400 N / mm2

-The cutting force and power required are high.

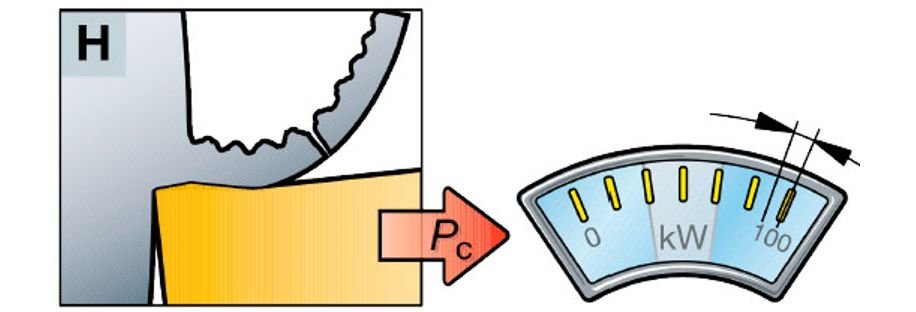

06-H caliber arec

What is hard steel?

-In the prospect of treatment, hardening steel is the smallest group.

-This group contains the quality of the hardness> 45–65 HRC.

-Ad the hardness range of the hard parts which is cut at 55-68 HRC.

Hard steel in group H is used in various industries, such as the automotive industry and its subcontractors, as well as the machine manufacturing and mold sector.

Usually, continuous, red and warm dandruff. This high temperature helps reduce KC1 value, which is important to help solve application problems.

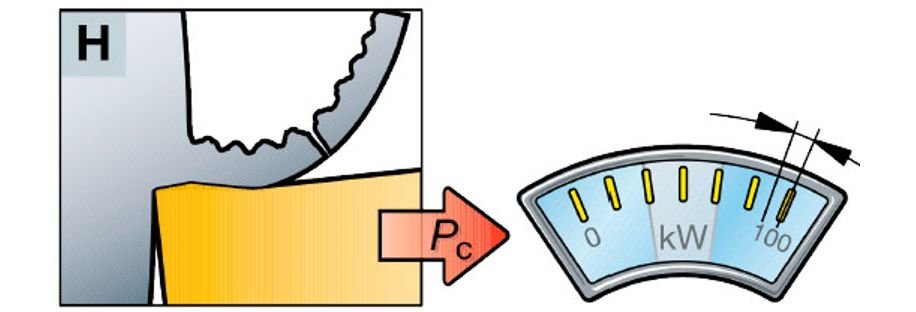

Treatment characteristics:

-The long chip material.

-The relatively good dandruff control.

-In the negative front corners.

-A cutting force unit: 2550-4870 n / mm2

-The cutting force and power required are high.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.