AlthoughPLA is a great 3D printing material, but it also has some drawbacks. For example, PLA has been criticized for being a little too brittle and also absorbing some moisture.

most people could sayThe next step up from PLA is PETG or ABS. Generally speaking, both are stronger and more durable than PLA, but neither is as easy to print. Fortunately, the PLA+busyBest location between PLA and ABS.

Through this article, Mohou.com will bring you more detailsintroduceRelevant properties of PLA+ material.

1. Overview

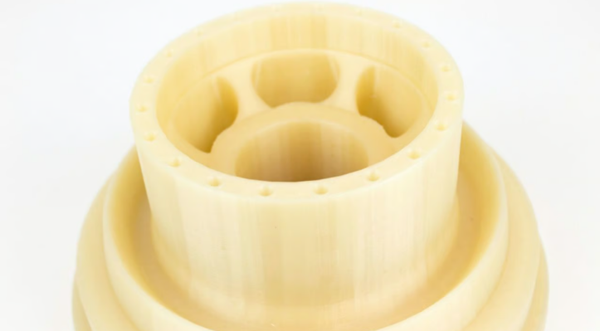

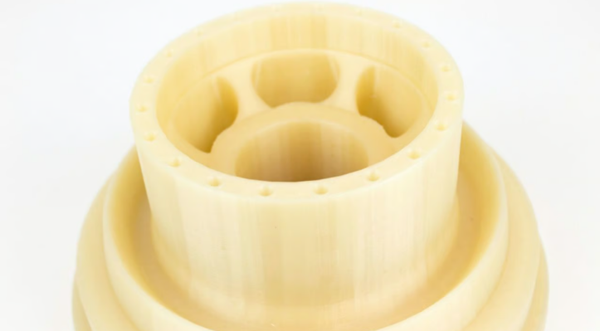

In some cases,PLA plus may not be better than regular PLA (Source: Rigid Ink)

1. Name

Although we use the term“PLA plus”, but not everything that falls into the “PLA plus” category is equal.

Will“PLA plus” is considered the general term for a broad class of enhanced PLA filaments. Within this group, manufacturers use different product names as a product marketing strategy, so not all PLA filament yarns have the same name.

For example,Brands such as eSun, Filiform and Kodak use a slight variation of “PLA+”. ColorFabb, on the other hand, calls its premium PLA blend “PHA” and some other companies use “Pro PLA.”

Often the different names are used simply for marketing purposes, but in some cases they actually represent different polymer blends. The best example isPHA, which stands for “polyhydroxyalkanoate”.

2. Formula

to useParts printed with ColorFabb PLA/PHA filament (Source: ColorFabb)

There is no single formula for PLA plus. Manufacturers have their own recipes and mixtures or source them themselves. In most cases, manufacturers remain discreet about their formulas. However, with a little digging, we can discover a few things.

becausePLA Plus is less brittle and absorbs less water than regular PLA, so it may contain some TPU, which helps it perform better.

two,PLA+ compared to PLA

by twinningPLA parts can be post-processed and you can still get impressive results (Source: BrittLiv via Instructables)

Print Settings

mostThe printing temperature of PLA extended filament is slightly higher than that of regular PLA. For example, eSun’s usual PLA printing temperature is 190-210℃, while PLA plus printing temperature is 205-225℃.

However, not all wiresare all the same, that’s why there is noSingle temperature rule for PLA plus. Most are between 200 and 230°C.

Performance

Performance is what people are willing to spend extra money onThe sole reason for PLA Plus. Thus, compared to PLA,most oftenPLA plus showed better results in stiffness and high temperature resistance tests.

Of course, the most significant performance improvement isThe PLA plus provides rigidity to the part. Regular PLA parts are difficult to bend and break quickly under pressure. However, PLA plus parts tend to have better pressure resistance because they bend better and resist pressure longer.

Price

Better material properties come at a higher price. Of course, the price depends on the manufacturer, but in most cases, expect to pay less than buying a regular device of the same size.Pay $5 to $15 more for PLA spools.

For example,3D-Fuel’s standard PLA costs around $30, while the premium PLA Pro costs around $40.

Color Options

ThisThe answer depends on the manufacturer. some forPLA plus comes in a limited color range, while others come in a variety of colors.

byeSun and 3D-Fuel are examples. eSun’s PLA plus comes in over 20 colors, while 3D-Fuel only has 7.

three,PLA+Compared to other materials

asLike PLA, PETG also comes in a variety of colors (Source: ColorFabb)

PETG

In most cases,PLA plus is easier to print. butIn terms of temperature resistance,PETG is most likely to win in most cases.

PETG requires higher printing temperatures and tends to be a little difficult to achieve the perfect profile setup. It has always been known for the enormous rigidity it provides. If you really want sturdy parts, PETG is probably your best choice.

On the other hand, if you don’t really need these sturdy parts but still want to print, thenPLA For more durable parts, choose the highest quality PLA.

ABS

The gap between PLA plus and ABS is larger than the gap between PLA plus and PETG. ABS is a difficult material to print, but it is incredibly resistant to temperature and impact, and is more flexible than PLA plus.

Let’s not forget,ABS also emits fumes when printing, but if temperature and impact resistance are your top priorities, ABS is the better choice, even though it is more difficult to print.

Four,write at the end

PLA is sufficient for most applications, with ease of use and rich options (Source: JustTry via Printables)

Finally, now that we have explained theEverything you need to know about PLA plus, then it’s time to discuss the value proposition.

If you primarily print aesthetic, non-functional models, GeneralPLA will work great. If you are printing parts that need to withstand a load, PLA plus is definitely worth a try.

There is no direct answer to the question of value. A lot depends on the filament material you choose, but it also depends on your budget and printing interests.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.