Further reading:Knowledge Points of 8K Resin 3D Printing

4K Resin 3D printingMachines are now the new normal and there is a lot to know, in this article,magic monkey networkI will learn the following questions about 4K resin 3D printer with you: What does 4K mean? What is the difference between 4K printers and other printers?

About 4K

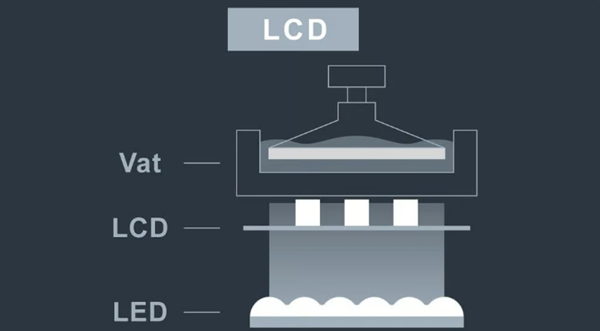

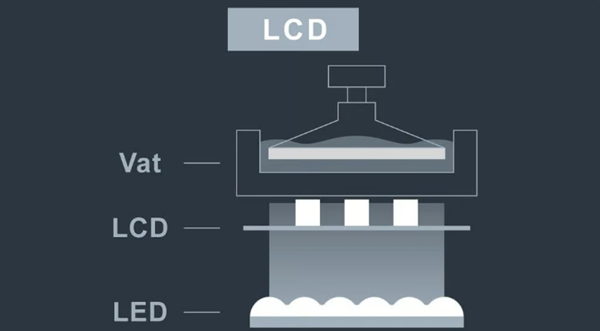

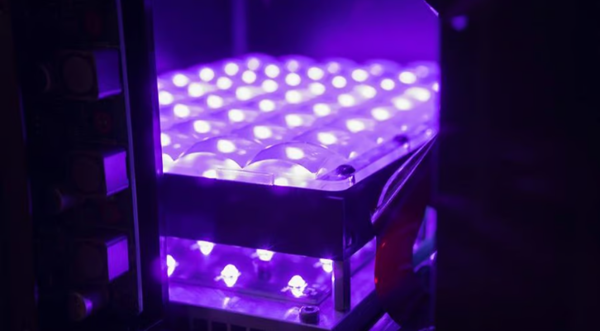

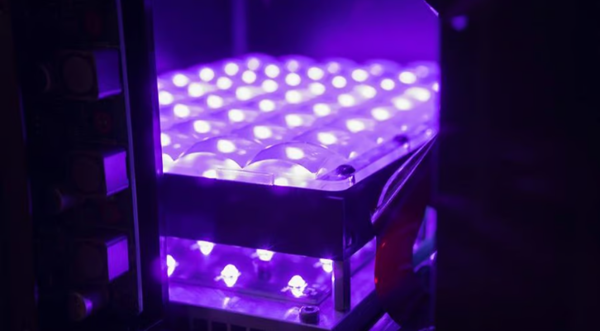

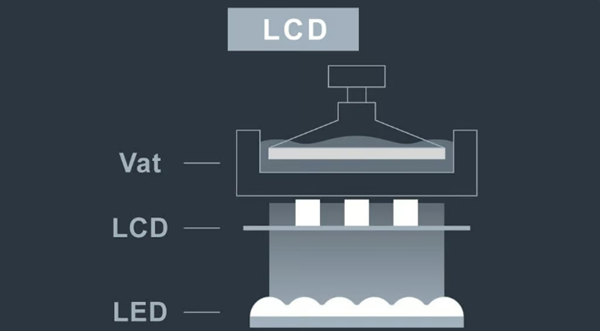

Curing the resin using UV light protected by an LCD screen (Source: Chanda Lalwani via Phrozen)

In a 4K resin 3D printer, the resolution of a 4K LCD is typically around 3840 x 2400 pixels (3840 is closer to 4000 or 4K). Resolution and screen size together determine pixel density, also known as pixels per inch (PPI). The smaller the screen size, the higher the pixel density; For users looking for the ultimate in detail, the higher the pixel density, the better. The most popular 4K resin printers typically have XY resolutions between 35 microns and 50 microns.

There are a few additional factors to consider when deciding which 4K resin 3D printer is best for you. Here we’ve put together five factors to help you evaluate different printers. These factors include price, manufacturing volume, LCD screen size, pixels per inch, and the lighting and masking technology used by the printer.

4K 3D printers are capable of reproducing even the smallest details of models (Source: All3DP)

First, check the prices of different 3D printers to see which ones fit your budget. Second, look at the print volume. When printing miniatures and short figures, the print area is more important than the print height. With the right build volume, you may want to print the models individually or you may be able to print multiple models at once. But this is not always the case, print volume depends on the size of your LCD screen, so make sure you know the difference!

As mentioned earlier, PPI is determined by screen size and resolution. Printers with a higher PPI will have no problem printing models with fine details. Finally, when we talk about the “technology” of a printer, we consider factors like the type of LCD screen and the light source.

Comparing 4K Resin 3D Printers to Other Resolution 3D Printers

Behind the scenes (or under) an LCD printer (Source: All3DP)

Let’s take a closer look at how 4K resin 3D printing compares to other 3D printing technologies and resolutions.

4K resin 3D printer and DLP printer

DLP printers use a light projector to project an image of the area to be printed, instantly curing the entire layer of selected areas. From this point of view, LCD printers are very similar to DLP. You can think of DLP as essentially functioning very similarly to a projector.

LCD printers work differently. As mentioned before, the UV light source emits light and the LCD screen blocks areas that should not be cured. However, the light used to cure the resin can damage the organic compounds present on the LCD screen. As a result, most LCD printers treat the screen as a consumable that must be replaced regularly, and replacement costs can be high. Recently, some 4K and 8K resin 3D printers have been equipped with monochrome LCD screens instead of RGB, which allows for a longer lifespan.

Although they print an entire layer at a time, the difference in printing time between LCD and DLP printers depends entirely on the machine itself as well as the specific features of the model and corresponding print settings.

The 4K LCD resin 3D printer is affordable, suitable for desktop use and compact. In comparison, DLP printers are mainly used for professional purposes and are more expensive.

2K, 4K, 8K resin 3D printer

Comparison of 4K printing (left) and 2K printing (right) (Source: All3DP)

2K, 4K, and 8K resin printers all use the same technology to cure the resin, but the main difference is the resolution of the LCD screen. The details of the printed model depend on the pixel size and density of the LCD screen and the manufacturing process of the photomask, rather than the resolution of the entire screen.

The resolution of the LCD screen of a 2K resin printer is approximately 2560 x 1620 pixels. Contrary to popular belief, 4K printers are not guaranteed to print more detailed models than 2K printers because, as previously mentioned, if the screen is larger, the pixel density will be lower. In fact, 2K printers with higher XY resolution can print more detailed final products. In terms of price, a 4K resin printer can cost between $50 and $250 more than a 2K printer with similar build volume.

As for 8K printers, the main difference is the number of pixels, and there are several options, such as the Phrozen Sonic Mega 8K, which has an LCD resolution of 7680 x 4320 pixels. The problem arises when the pixel count is higher but the screen is larger. This results in lower pixel density and the quality is not really reflected in the resolution. There are some exceptions, however: some 8K printers offer truly superior quality while maintaining LCD screen sizes similar to 4K printers. With improved resolution and print volumes, these printers are worth considering as long as they meet your needs, as they come at a much higher price.

In summary, the main differences between 2K, 4K and 8K resin printers are their LCD resolution, print volume and price, while the printing technology and model details remain largely consistent across the three categories.

Is there really a difference between 2K and 4K?

For most people, there is little difference between 2K (left) and 4K (right) 3D printing (Source: JuanHidalgo Miniatures via YouTube)

For the same size printer, the resolution of some prints increases from 2K to 4K, which is difficult to detect with the naked eye. Therefore, for those looking to print functional items, this upgrade is not worth it. On the other hand, users who print highly detailed models such as miniatures or R-figures will greatly benefit from smaller pixels.

As mentioned earlier, the key to a 4K LCD printer is pixel size, not screen resolution. More specifically, the number of pixels is related to the size of the build plate.

If it’s a larger printer with a 4K LCD screen, the pixels will be larger, giving it a similar XY resolution to a smaller 2K screen. Resolution terms like 2K and 4K are only useful if you have more information about the printer. Therefore, 4K in a 4K resin 3D printer does not automatically guarantee superior print quality.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.