introduce

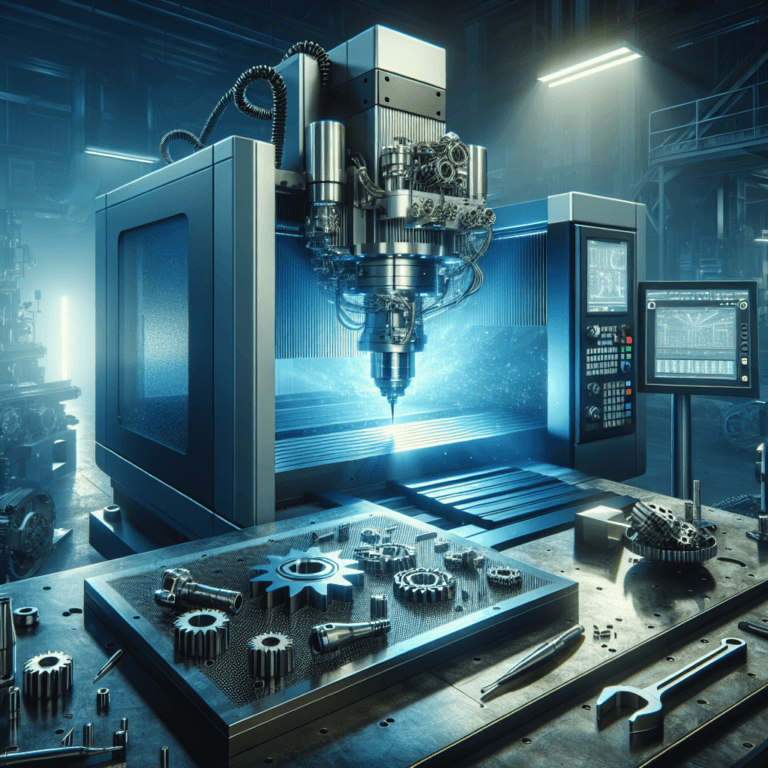

Computer Numerical Control (CNC) machining has revolutionized manufacturing, providing unparalleled precision, efficiency and versatility in the production of complex parts. As technology advances, so does innovation in CNC machining. This article delves into cutting-edge developments in CNC machining to increase productivity while maintaining high standards of quality and precision.

1. Evolution of CNC machining technology

CNC machining as we know it originated in the late 1940s and early 1950s, evolving from basic automated lathes into sophisticated systems that can produce highly complex designs. Technological advances in CNC machining over the decades include the integration of computer technology, software improvements, and advances in materials science. Today, the industry is experiencing an unprecedented wave of innovation, further driving the development of CNC machining.

1.1 Additive manufacturing integration

One of the key recent developments in CNC machining is the integration of additive manufacturing (3D printing) into traditional subtractive processes. This hybrid approach allows manufacturers to combine the best of both worlds, enabling the production of complex geometries that were previously unimaginable. By leveraging CNC machining and additive manufacturing, manufacturers can minimize material waste while maximizing design capabilities.

1.2 Advanced software solutions

The use of advanced software solutions plays a vital role in enhancing CNC machining processes. Modern software now uses artificial intelligence (AI) and machine learning-driven algorithms to optimize cutting paths and tool selection. These smart systems enable predictive maintenance, reducing downtime and extending machine life. Additionally, parametric modeling allows real-time adjustments to design specifications to accommodate rapid changes in production requirements.

1.3 Internet of Things and Intelligent Manufacturing

The Internet of Things (IoT) is transforming CNC machining into smarter, more connected systems. By connecting machines and tools to the Internet, manufacturers can monitor performance metrics in real time and analyze data to inform the decision-making process. This connectivity enables better workflow management, enhances predictive maintenance planning, and enables remote monitoring, ensuring increased efficiency and reduced operating costs.

2. The role of materials in CNC machining innovation

Innovations in CNC machining are not limited to the technology itself—advances in materials science also play a key role in improving accuracy and efficiency. New materials with superior properties can improve the performance of CNC machine tools, allowing them to produce higher quality products.

2.1 Composite materials

The emergence of advanced composite materials, including carbon fiber reinforced polymers and metal matrix composites, has greatly impacted CNC machining capabilities. These materials are lightweight yet extremely strong, making them ideal for aerospace, automotive and medical applications. CNC machining enables precise shaping of these materials, improving the structural integrity and performance of the final product.

2.2 High performance alloys

Recent developments in metallurgy have resulted in high-performance alloys capable of withstanding extreme temperatures and corrosive environments. These alloys, such as titanium- and nickel-based superalloys, present unique machining challenges that require advanced techniques and tooling. Innovative CNC machining technologies such as high-speed machining and laser-assisted machining have been developed to process these demanding materials with increased accuracy and efficiency.

3. Automation and robotics in CNC machining

The introduction of automation and robotics into CNC machining processes represents a major leap in manufacturing efficiency. Automated systems can perform repetitive tasks with a precision and speed that far exceeds human capabilities.

3.1 Collaborative robots (Cobots)

Collaborative robots are designed to work alongside human operators to increase productivity while ensuring safety. By taking over repetitive and laborious tasks, collaborative robots free up skilled labor to focus on more complex operations. Additionally, cobots can be programmed to adapt to a variety of tasks and can be easily reassigned to different machining processes as needed.

3.2 Fully automatic CNC machine tools

The rise of fully automated CNC machine tools allows manufacturers to reduce labor costs and increase output. These machines can operate continuously, allowing for 24/7 production capabilities with minimal human intervention. Innovations such as automatic tool changers and integrated quality control systems further improve efficiency and reduce the possibility of human error.

4. Improve CNC machining accuracy

Precision is the hallmark of CNC machining, and several innovations are driving improvements in this important aspect of manufacturing.

4.1 High-precision processing technology

Technologies such as micromachining and ultra-precision machining are becoming increasingly important. Micromachining can produce complex parts with tolerances in the micron range. These technologies involve specialized tooling and machining processes to create parts for industries such as medical devices and microelectronics.

4.2 Advanced cutting tools

The development of advanced cutting tools with coatings such as diamond-like carbon (DLC) and cubic boron nitride (CBN) has driven improvements in wear resistance and cutting efficiency. Not only do these cutting tools last longer, they also process faster, further increasing overall productivity.

4.3 Precision measurement and quality control

Innovations in precision measurement and quality control systems are critical to maintaining high standards in CNC machining. Advanced sensors and real-time monitoring systems help ensure that all aspects of the machining process remain within specified tolerances. Technologies such as laser scanning and coordinate measuring machines (CMM) enable continuous evaluation throughout the production process.

5. Sustainability of CNC machining

As manufacturing grows, sustainability is becoming a key focus area for CNC machining. Innovations that promote environmentally friendly practices are gaining traction, in line with the global push for sustainable manufacturing.

5.1 Reduce material waste

Advanced CNC machining technology helps minimize material waste through efficient cutting strategies and the utilization of new composite materials. As manufacturers work to reduce their carbon footprint, technologies such as remanufacturing and recycling leftover materials are becoming increasingly popular.

5.2 Energy-saving machinery

The development of energy-saving CNC machine tools not only reduces operating costs but also reduces environmental impact. Innovations such as regenerative braking in CNC systems and energy-saving drive systems can significantly reduce energy consumption during operation, thus promoting more sustainable manufacturing methods.

in conclusion

Innovations in CNC machining are a driving force in manufacturing, improving efficiency, precision and sustainability. As technology, materials and automation continue to advance, they are redefining the capabilities of CNC machine tools. The integration of IoT, artificial intelligence and advanced software makes the entire process smarter and more responsive, paving the way for future growth and further raising the bar for manufacturing excellence.

As industries continue to embrace these innovations, CNC machining will continue to be at the forefront of creating high-quality products tailored to specific needs while adhering to principles of efficiency and sustainability. Manufacturers who invest in these technologies and embrace these changes will find themselves better prepared to meet the challenges of a dynamic and evolving market.

FAQ section

Q1: What is CNC machining?

A1: CNC machining (computer numerical control machining) is a manufacturing process in which preprogrammed computer software controls the movement of factory tools and machinery. The technology enables high-precision operations, allowing the production of complex shapes and parts.

Q2: How to improve the efficiency of CNC machining?

A2: CNC machining improves efficiency by automating production processes, thereby reducing human errors and increasing speed. Advanced technologies such as real-time monitoring and artificial intelligence-driven software can further optimize workflow and minimize downtime.

Q3: What materials can be used for CNC processing?

A3: CNC machining can process a variety of materials, including metals (such as aluminum, steel, titanium), plastics (such as polycarbonate and acrylic), composite materials (carbon fiber and fiberglass), and wood. Material selection often depends on the requirements of the specific application.

Q4: What are the benefits of combining additive manufacturing with CNC machining?

A4: Combining additive manufacturing with CNC machining allows manufacturers to create complex geometries with minimal waste. This hybrid approach combines additive layer building technology with subtractive methods, enhancing overall manufacturing capabilities and flexibility.

Q5: Are there any safety issues with CNC machining?

A5: Yes, CNC machining involves several safety issues, including the risk of injury from moving parts, exposure to high temperatures, and the risk of handling sharp tools. However, safety protocols, training, and the use of collaborative robots can mitigate these risks.

By integrating these advancements and focusing on continuous improvement, the industry can expect CNC machining to remain an important part of the manufacturing process, driving future innovation and excellence.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.