6da Geedi-socodka Wax-soo-saarka ee ugu Muhiimsan ee Hawada Sare sanadka 2025

Aug 19,2024

Aug 19,2024

Aerospace manufacturing is rapidly evolving with new technologies and materials that drive the development of high-performance components. To stay competitive in this dynamic field, understanding the latest advancements in manufacturing processes is essential. In 2024, six key processes stand out, each contributing to the design, efficiency, and reliability of aerospace components.

- Precision Manufacturing for Aerospace Components

- Composite Materials and Advanced Manufacturing

- Wax-soo-saarka Wax-soo-saarka (Daabacaadda 3D)

- Advanced Materials and Composite Technologies

- Isku-dhafka Qalabka Wacan

- Digital Twin and Modeling Technologies

Precision CNC Machining for Aerospace Components

Precision CNC Machining is crucial in aerospace engineering, requiring components with tight tolerances and high reliability.

GreatLight's CNC Machining Capabilities

At Iftiin weyn, our expertise in CNC machining allows us to meet the stringent demands of the aerospace industry. We utilize cutting-edge CNC technologies to produce components with exceptional precision and consistency. Our capabilities include:

- Khibrada Agabka: Machining high-performance alloys like titanium, aluminum, and nickel-based superalloys.

- Mashiino Horumarsan: Utilizing 5-axis CNC machines for complex geometries and multi-axis machining.

- Hubinta Tayada: Rigorous inspection processes to ensure every component meets aerospace standards.

Alloys Waxqabadka Sare

| Nooca Alwaax | Codsiyada | Faa'iidooyinka Key |

|---|---|---|

| Alloys Titanium | Airframes, Engine Components | Saamiga xoogga-ilaa-miisaanka sare, iska caabinta daxalka |

| Nikel-ku-saleysan Superalloys | Turbine Blades, Heat Exchangers | Excellent thermal stability, resistance to mechanical stress |

Composite Materials and Advanced Manufacturing

Composite materials offer significant benefits over traditional metals, such as weight reduction and improved performance.

| Qalabka isku dhafan | Codsiyada | Faa'iidada |

|---|---|---|

| Polymers-Xoojinta Kaarboon Fiber (CFRPs) | Aircraft Structures, Spacecraft | High strength-to-weight ratio, fuel efficiency, and payload capacity |

| Isku-dhafka Is-bogsiinta | Morphing Wings, Structural Repairs | Automatic damage repair, extended component lifespan, reduced maintenance |

Wax-soo-saarka Wax-soo-saarka (Daabacaadda 3D)

Additive manufacturing is transforming aerospace production by enabling the creation of complex components with minimal waste.

Key Benefits of Additive Manufacturing

- Joometries isku dhafan: Allows for intricate designs that traditional methods can't achieve.

- Waxtarka Shayga: Reduces waste and cuts costs by using only the necessary material.

- Prototyping Speed: Accelerates development by enabling rapid design iterations.

| Codsiyada Shaqaalaha Cusub | Benefit |

|---|---|

| wadanay | Fast design iteration, reduced development time |

| End-Use Components | Lightweight, consolidated parts with fewer points of failure |

Advanced Materials and Composite Technologies

Advanced materials like nanocomposites and shape memory alloys are revolutionizing aerospace manufacturing.

| Nooca Waxyaabaha | Guryaha muhiimka ah | Codsiyada |

|---|---|---|

| Nanocomposites | Korantada kulaylka iyo korantada oo la xoojiyey | Heat shielding, propulsion systems |

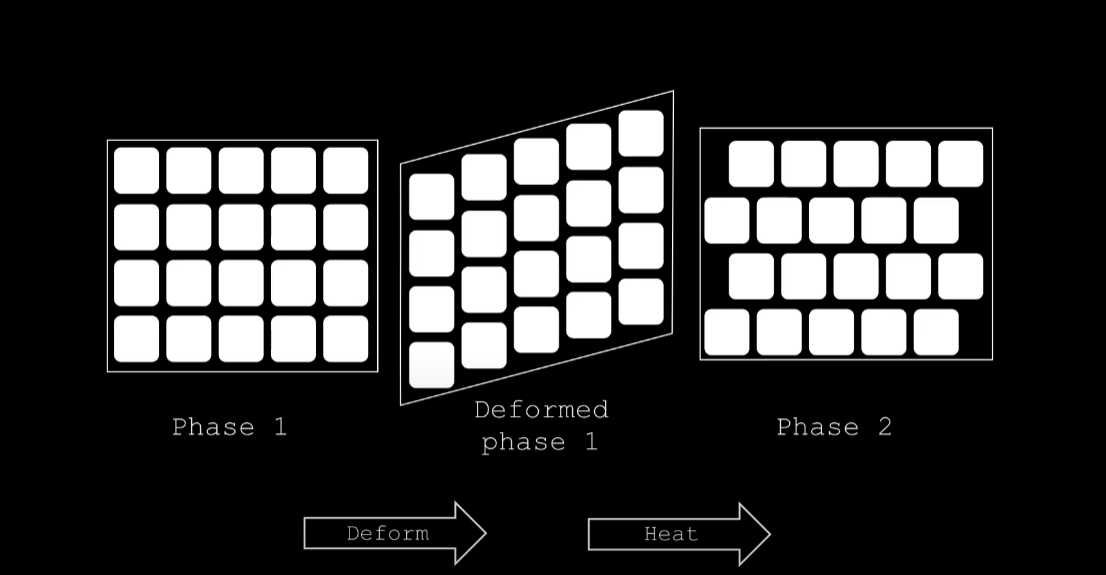

| Shape Memory Alloys (SMAs) | Ability to return to a predetermined shape | Actuators, adaptive systems |

Isku-dhafka Qalabka Wacan

Smart materials adapt to changing conditions, enhancing the functionality and durability of aerospace components.

| Qalabka Wacan | function | Codsiyada Shaqaalaha Cusub |

|---|---|---|

| Qaababka Xusuusta Daaha | Adaptive structures | Aircraft wings, engine components |

| Qalabka Piezoelectric | Xakamaynta gariirka | Sensors, stability systems |

Digital Twin and Modeling Technologies

Digital twin technology creates virtual replicas of physical systems, enabling better design, testing, and maintenance.

| Codsiyada Shaqaalaha Cusub | Benefit |

|---|---|

| Dayactir saadaalin ah | Early detection of potential issues, reduced downtime |

| Hagaajinta Naqshadeynta | Enhanced accuracy in design, faster prototyping cycles |

Ugu Dambeyn

The aerospace industry in 2024 is characterized by rapid advancements in manufacturing processes, materials, and technologies. GreatLight is at the forefront of these developments, offering advanced CNC machining solutions that meet the exacting demands of the aerospace sector. By staying informed about these trends and leveraging our cutting-edge capabilities, we ensure that our clients receive the highest quality components, driving the next generation of aerospace innovation.

Tel/WeChat:

Tel/WeChat:  E-mail:

E-mail:

Bogga Hore

Bogga Hore

Tilmaamaha Dhammaystiran ee Birta Madow. Iyo Sida Loo Madoobeeyo Birta

Tilmaamaha Dhammaystiran ee Birta Madow. Iyo Sida Loo Madoobeeyo Birta