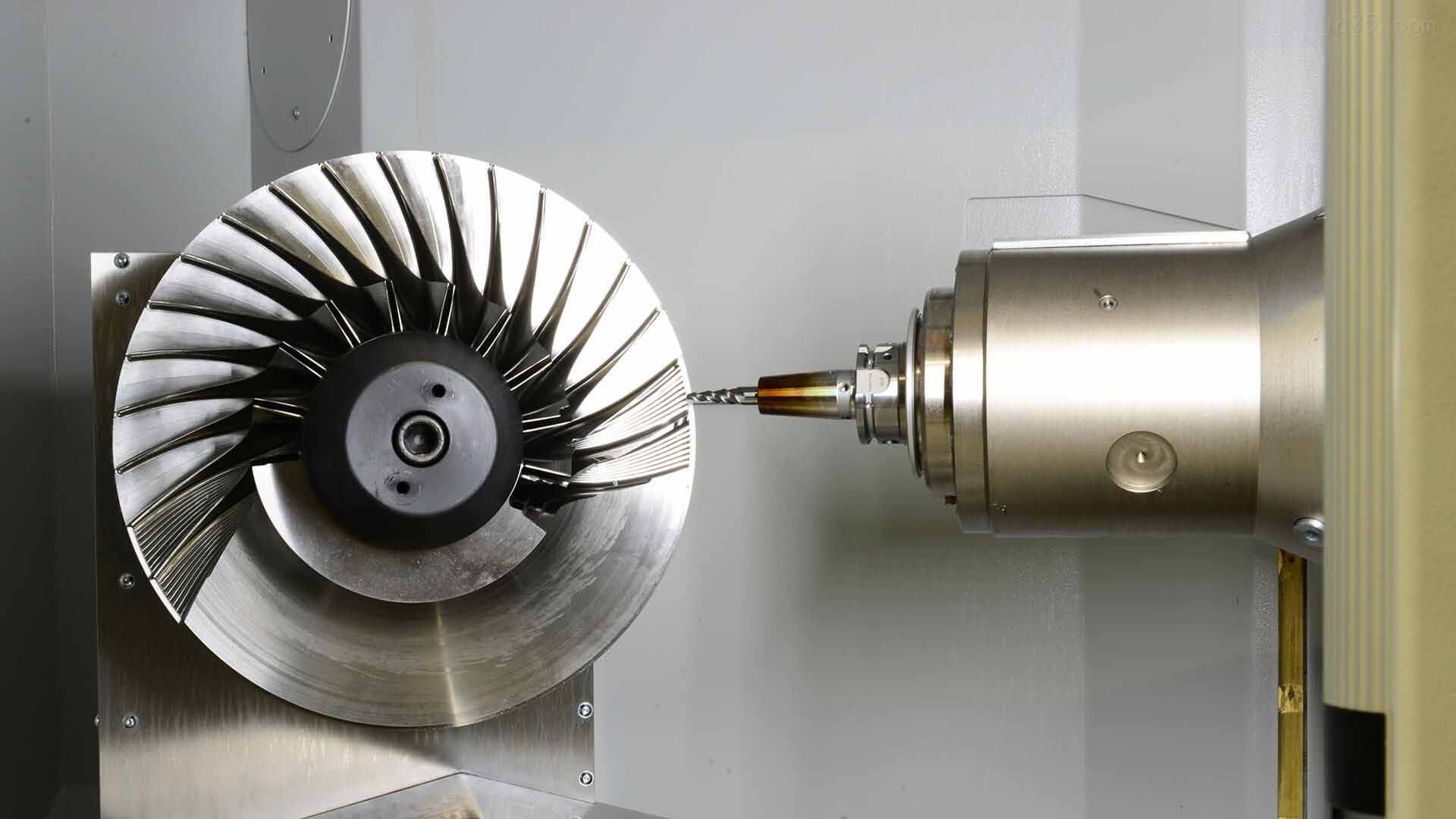

Adeegyada Mashiinka CNC ee Khadka Tooska ah ee 5 Axis

Makiinadaha 5-axis waa hab wax ku ool ah oo loogu talagalay makiinada qaybaha adag. Annagoo ah soo saaraha qaybaha gaarka ah ee CNC, waxaanu hubineynaa qaybaha makiinada ee tayo sare leh. Dalab kasta wuxuu ka kooban yahay warbixintayada kormeerka caadiga ah. Warbixinno iyo shahaadooyin dheeraad ah ayaa la heli karaa marka la codsado, soo gudbi dalab si loo bilaabo. Wax soo saarka qiimaha jaban ee baahida loo qabo iyo keenista waqtiga ku habboon ayaa ah heerarka adeegyadayada makiinada CNC ee 5-axis. Awoodo wax soo saar oo ballaaran si loo daboolo baahiyahaaga wax soo saarka.

- Hel qiimeyn bilaash ah 2 saacadood gudahood

- 40+ biro iyo balaastig, 10+ oo dusha sare ah ayaa la dhammeeyay

- Noocyada mashiinka lagu sameeyay 1 maalin gudaheed

- Naqshad gaar ah oo ku xidhan faahfaahinta macaamiisha

Xigasho Machining ah oo Degdeg ah oo 5 dhidib ah

Adeegyada Wax-soo-saarka ee Khadka Tooska ah - Soo-saarista Qiimaha Jaban ee Marka La Dalbado, Bixinta Waqtiga

Ma u baahan tahay Mashiinka CNC ee baahida loo qaboDukaanka mashiinka saxda ah ee GreatLight wuxuu bixiyay adeegyo mashiinno CNC ah oo 5axis ah iyo jarista saxnaanta ah muddo 18 sano ah, isagoo bixinaya adeegyo wax soo saar degdeg ah oo tayo sare leh oo loogu talagalay sameynta qaybaha gaarka ah iyo soo saarista alaabada.

Waxyaabaha loo yaqaan "prececision machining"

Adeegyada jarista laysarka, jarista balaasmaha, jarista biyaha, foorarsiga, alxanka iyo shaambadda

Xigasho Makiinad Sax ah oo Degdeg ah

Aqoonta

GreatLight waxay la wadaagtaa kobac joogto ah oo ah 300%+ sanadba sanadka ka dambeeya. Kuwani waa sifooyinka naga dhigaya kuwo ka soocan. Isku day mishiinnadayada CNC marka aad u baahato.

Warbixinada Tayada

Dalab kasta oo ku yaal madalkeenna, waxaan ku siin karnaa liis dhammaystiran oo warbixinno tayo leh iyadoo loo eegayo codsiyada macaamiisha. Oo ay ku jiraan laakiin aan ku xaddidnayn:

- Warbixinta baadhista

- Warbixin cabbir buuxa leh

- Warbixinta tijaabada agabka

Certificate

Annagoo ah soo-saare wax-soo-saar oo khibrad toban sano ah u leh soo-saarista mashiinnada wax-soo-saarka ee baahida loo qabo, waxaan bixinnaa shahaadooyin caadi ahaan loo baahan yahay, oo ay ku jiraan laakiin aan ku xaddidnayn:

- ISO 9001: 2015

- RoHS

- CE

Kormeerka Qodobka Koowaad (FAI)

Qaybaha birta xaashida ah ee mugga yar iyo dalabaadka mashiinka CNC ee ka badan 50 cutub ama 5000 USD wadarta qiimaha, kormeerka koowaad ee maqaalka ayaa la heli karaa marka la codsado.

Khibradeenna ku aaddan tirooyinka

|

|

|

|

| 2000 + | 50000 + | 30 + | 18 + |

| Shirkadaha loo adeego | Qaybaha CNC ee la soo saaray | Dalalka la diray | Sannado ganacsi |

Adeegyada Makiinadaha CNC ee 5 Axis - Shirkadda Wax Soo Saarka CNC ee Sax ah oo leh Xarunta Makiinadaha 5 Axis

Mashiinka CNC ee 5-Axis Soo saarista baahida loo qabo Dhammaystir tayo sare leh, xulashooyin badan oo agab ah, iyo dulqaad sax ah ayaa ka dhigay mashiinka CNC inuu noqdo tignoolajiyada ugu wanaagsan ee qaybaha wax soo saarka taxanaha ah. Qaybaha mashiinada CNC online.

Ma u baahan tahay Adeegga saxda ah ee leexashada CNC? U gudubka GreatLight qaabka wax soo saarka ee baahida loo qabo wuxuu siinayaa Iibsadaha dabacsanaan wax soo saar oo dheeraad ah. Aqoon-is-weydaarsiga saxda ah ee mashiinka GreatLight, injineeradayada iyo farsamayaqaannadayadu waxay si fudud u soo saari karaan qaybo looga baahan yahay shan dhidib oo ku jira adeegga mashiinka 5-dhidib. Iyadoo aan loo eegin sida qaybaha mashiinka CNC u adag yihiin, tallaabo kasta waxaa lagu fulin doonaa si adag, iyadoo la bixinayo qaybo mashiinka 5-dhidib oo heer sare ah iyo muujinta heerarka tayada ugu sarreeya. Soo-saaraha mashiinka mashiinka GreatLight (www.GreatLight-cncmaching.com) wuxuu dabooli karaa baahiyahaaga mashruuca.

GreatLight oo ka mid ah mashiinnada CNC ee ugu fiican Shiinaha waa doorasho ku habboon haddii aad raadineyso Soo-saare CNC Machining ama Dukaanka CNC si aad u soo saarto badeecooyin yaryar, dhexdhexaad ah, oo waaweyn oo leh mug yar ama wax soo saar ballaaran. Shaqaalaheenna si gaar ah u tababaran oo khibrad leh ayaa sameeya qaybaha si waafaqsan. Iyada oo ah mid ka mid ah soosaarayaasha mashiinka CNC ee ugu fiican Shiinaha, Mashiinka Mashiinka CNC ee Khadka Tooska ah ee 100 CNC, taasoo ka dhigaysa doorasho aad u fiican oo loogu talagalay tijaabinta degdega ah iyo socodsiinta wax soo saarka mugga hooseeya ilaa kan sare, xigashooyinka qaybaha CNC ee degdegga ah, wax soo saarka qiimaha jaban ee baahida loo qabo, 30+ agab oo dhammaystiran oo dusha sare ah oo dhammaystiran oo u adkeysan kara ilaa 0.005mm. Isku day daabacaaddayada dalabka 3D.

Maxaad u Doorataa Adeegyada Mashiinka CNC ee GreatLight 5 Axis

- Xaruntayada mashiinka ee shan dhidib leh waxay qaadataa naqshad dhisme oo tayo sare leh oo ugu fiican, iyadoo saxnaanta mashiinka ay tahay + / - 0.003mm

- Waxaan isticmaali karnaa xarumaha mashiinka 3/4/5 axis oo ay ku jiraan 30 nooc oo agab ah sida aluminium, bir, naxaas, iyo titanium si aan u farsameyno alaabada CNC ee saxda ah si ay u buuxiyaan qeexitaanno kala duwan.

- Habka dhammaystiran iyo nidaamka xakamaynta tayada ee adag ayaa qiimeeya tayada marxalad kasta oo diyaargarowgeenna ah, wax soo saarkeenna, iyo kormeerkeenna si loo hubiyo in tayada qaybaha CNC ee 5-dhidib leh ay had iyo jeer buuxiyaan shuruudaha

- Hadda qaybo mashiinka shiididda 5-axis ah oo gaar loo sameeyay oo leh qiimo tartan ah, dib u habeyn degdeg ah, wax soo saar la hagaajiyay, iyo keenista waqtigii loogu talagalay. Fadlan sidoo kale hubi adeegga shiididda mashiinka CNC.

Waa maxay 5 Axis Machining?

Makiinadaha 5-axis waxay ka tirsan yihiin makiinada Multiaxis. Makiinadaha 5-axis waxaa badanaa loo isticmaalaa warshadaha halkaas oo shaqada loo turjumo si toosan oo leh saddex dhidib (badanaa x, y, iyo z) iyo isgoyska qalabka ayaa awood u leh inuu ku wareego ku darista 2 dhidib.

Hadda waxaa jira nidaamyo badan oo software ah oo CAM ah (wax soo saarka kombiyuutarku caawiyo) oo diyaar u ah inay taageeraan mishiinnada multiaxis oo ay ku jiraan software-ka si toos ah ugu beddeli kara waddooyinka qalabka 3-axis waddooyin qalab 5-axis ah. Waxaan sidoo kale bixinnaa farsamaynta tusaalaha birta xaashida ah.

Faa'iidooyinka 5 Axis Machining

- Tirada shaqada aadanaha waa la dhimayaa haddii qaybta si kale loo rogo gacanta inta lagu jiro farsamaynta.

- Dhammaystir dusha sare oo wanaagsan ayaa la heli karaa iyadoo qalabka si tangically ah loogu dhaqaajiyo dusha sare (halkii laga dhaqaajin lahaa shaqada ku wareegsan wareegga).

- Qaybo aad u adag ayaa la soo saari karaa, gaar ahaan qaybo leh godad qaloocan.

- Nolosha qalabka oo korodhay sababtoo ah awoodda lagu gaari karo xaglo ugu fiican oo u dhexeeya qalabka iyo dusha mashiinka.

- Qaybo tayo sare leh. Wixii markii hore loo baahnaa dejinta badan hadda waxaa lagu fulin karaa dhowr jeer oo keliya haddii aysan ahayn mid, taasoo yareyneysa tallaabooyinka oo yareyneysa fursadda qaladka.

- Soo gaabi wareegga R & D ee alaabada cusub adoo adeegsanaya xigashadayada mashiinka CNC ee degdegga ah.

- Soo gaabi habka wax soo saarka oo fududee maaraynta wax soo saarka.

Machining-ka 5-ta Axis iyo Machining-ka 3+2

Makiinadaha 5-axis way ka duwan yihiin makiinada 3+2-axis. Makiinadaha 5-axis ee CNC ama makiinada waxay ku lug leeyihiin hagaajin joogto ah oo qalabka jarista ah oo ku teedsan dhammaan shanta axis si ay caaradda qalabka ugu habboon ugu toosan tahay qaybta. Makiinadaha 3+2, oo sidoo kale loo yaqaan makiinada 5-axis ama 5-axis oo la calaamadeeyay, waa barnaamij 3-axis ah oo qalabka jarista uu ku xiran yahay xagal iyadoo ku xiran labada axis ee wareega. Makiinadaha 3+2 waxay u baahan yihiin inay joogsadaan oo ay bilaabaan inta u dhaxaysa dib-u-hagaajinta qalab kasta, halka makiinada 5-axis aysan u baahnayn taas, sidaa darteed xawaaraheeda si weyn ayaa loo hagaajiyay. Intaa waxaa dheer, 5-axis oo ku habboon makiinada CNC ayaa loogu talagalay codsiyo badan sababtoo ah awoodooda xooggan. Guud ahaan, makiinada 3+2 waxay u shaqeysaa farsamaynta diyaaradda mana dhammaystiri karto makiinada leexleexan ama gaarka ah, halka xarunta makiinada 5-axis ay ku habboon tahay makiinada dusha sare ee kala duwan. Isku day qiimaha CNC ee khadka tooska ah ee Shiinaha.

Qaybaha saxda ah ee gaarka ah

La xiriir mid ka mid ah shirkadaha ugu fiican ee shaambadaynta birta - warshadda GreatLight CNC hadda, bilaash. Waad la yaabi doontaa farsamadeena degdega ah ee mashiinka.

Dhammaan macluumaadka iyo soo gelinta waa ammaan iyo qarsoodi iyadoo la adeegsanayo soo saaraha qaybaha wax lagu shiido ee CNC ee la isku halleyn karo.

- Dukaanka mashiinka CNC ee GreatLight saxnaanta ayaa ka gudbay shahaadada ISO9001

- Warbixinnada kormeerka cabbir buuxa marka la codsado

- Shahaadooyinka agabka iyo warbixinnada tijaabada ayaa la heli karaa marka la codsado

- Kormeerka dufcadda oo la jaan qaadaya ISO2859

- Heshiisyo adag oo NDA ah oo lala galay dhammaan iibsadayaasha

- Wax soo saar qiimo jaban oo ku salaysan baahida, keenista waqtiga ku habboon

- Waxaan nahay shirkadda daabacaadda 3D ugu sarreysa

Xigasho Machining ah oo Degdeg ah oo 5 dhidib ah

Qaybaha Mashiinka CNC ee Gaarka ah ee 5-ta Dhidib

Waxaan leenahay waayo-aragnimo waana saxnaa adeegyada samaynta biraha xaashida lagama maarmaan u ah in fikraddaada la soo bandhigo.

Tan waxaa ka mid ah adeegyada sida dulqaad sare iyo jarista laysarka oo dhumucdiisuna ballaaran tahay, awoodaha foorarsiga, leexashada mishiinnada CNC, iyo ikhtiyaarrada kale ee ka dambeeya farsamaynta.

Faahfaahinta cabbirka |

Tolerance |

|---|---|

| Gees ilaa gees, dusha sare oo keliya | +/- 0.005 inji |

| Cidhif ilaa god, dusha sare oo keliya | +/- 0.005 inji |

| God ilaa god, dusha sare oo keliya | +/- 0.005 inji |

| U leexo geeska / godka, dusha sare oo keliya | +/- 0.010 inji |

| Gees ilaa muuqaal, dusha sare oo badan | +/- 0.030 inji |

| Qayb ka sarreysa, dusha sare oo badan | +/- 0.030 inji |

| Laabi xagal | +/- 1° |

| Sida caadiga ah, geesaha fiiqan waa la jabin doonaa oo waa la burburin doonaa. Cidhifyada muhiimka ah ee laga tagi doono kuwo fiiqan, fadlan ogow oo ku cad sawirkaaga. | |

Alaabta la heli karo

GreatLight sida soo saaraha mashiinka CNC waxay bixisaa xulasho ballaaran oo ah walxo bir ah iyo balaastig ah oo leh midabyo kala duwan, buuxin, iyo ikhtiyaarro adag. Agabkan waxaa lagu waafajiyay liis ballaaran oo awoodaha wax soo saarka ah si loo daboolo shuruudaha gaarka ah ee mashaariicdaada.

Qalabka Mashiinka Birta CNC

biraha |

Description |

Details |

|---|---|---|

|

CNC Machining Aluminum Alloys: Aluminium 6061, Aluminium 5052, Aluminium 2024, Aluminium 6063, Aluminium 7050, Aluminium 7075, Aluminium MIC-6 |

Heerka sare-u-badan miisaanka |

|

|

CNC Machining steel Alloys: Bir aan miridh lahayn 15-5, Bir aan miridh lahayn 17-4, Bir aan miridh lahayn 18-8, Bir aan miridh lahayn 303, Bir aan miridh lahayn 316/316L, Bir aan miridh lahayn 416, Bir aan miridh lahayn 410, Bir aan miridh lahayn 420, Bir aan miridh lahayn 440C |

Iska caabin wanaagsan oo daxalka ah + Adkaysi Sare |

|

|

Qalabka Birta ee CNC Machining: Bir 1018, Bir1215, Bir4130, Bir4140, Bir4140, PHSteel 4340, Bir A36 |

Makiinad wanaagsan + Gudbin koronto oo heer sare ah |

|

|

CNC Machining Brass Alloys: Copper 260, Copper 360 |

Makiinad wanaagsan + Gudbin koronto oo heer sare ah |

|

|

CNC Machining Copper Alloys: Naxaas 101, Naxaas C110 |

>99.3% Nadiif ah + Koronto-qaadis heer sare ah |

|

|

CNC Machining Titanium Alloys: Titanium (Fasalka 2), Titanium (Fasalka 5) |

Iska caabbinta daxalka + Xoog sare oo la isku dhejiyo |

Daaweynta Dusha Sare ee Adeegyada Habaynta Birta Xaashida ah

Aluminum

Aluminiumku waa bir aad u dhuuban, taasoo sahlaysa in la farsameeyo. Maaddadu waxay leedahay saamiga xoog-ilaa-miisaanka oo wanaagsan, waxaana laga heli karaa noocyo badan oo loogu talagalay codsiyo kala duwan.

copper

Naxaasku wuxuu muujiyaa dabacsanaan kuleyl oo heer sare ah, dabacsanaan koronto iyo balaastiknimo. Sidoo kale waa mid aad u dhuuban, u adkaysta daxalka waana la isku dhejin karaa si fudud.

naxaas

Naxaasku wuxuu leeyahay sifooyin la jecel yahay oo loogu talagalay dhowr adeegsi. Waa is jiidjiid yar, wuxuu leeyahay koronto aad u fiican wuxuuna leeyahay muuqaal dahabi ah (naxaas ah).

ahama Steel

Birta aan lahayn birta waa birta kaarboonka yar ee bixisa sifooyin badan oo loo raadsado codsiyada warshadaha. Birta aan lahayn birta badanaa waxay ka kooban tahay ugu yaraan 10% chromium miisaan ahaan.

titanium

Titanium wuxuu leeyahay sifooyin badan oo agab ah oo ka dhigaya birta ugu habboon ee loogu talagalay codsiyada adag. Astaamahan waxaa ka mid ah iska caabin aad u fiican oo ka dhan ah miridhka, kiimikooyinka iyo heerkulka xad-dhaafka ah. Birtu waxay sidoo kale leedahay saamiga xoogga iyo miisaanka oo aad u fiican.

bacyaal

Balaastiggu sidoo kale waa ikhtiyaar aad loo jecel yahay oo loogu talagalay mashiinka CNC sababtoo ah xulashooyinkeeda ballaaran, qiimo ahaan hooseeya, iyo waqtiga loo baahan yahay ee mashiinka si dhakhso leh loo farsameeyo. Waxaan bixinaa dhammaan balaastikada caadiga ah ee adeegyada mashiinka CNC.

- POM

- nylon

- ABS

- FARIIN

- PTFE

- PC

- HDPE

- PVC

- PMMA

- PET

- PP

Machining sax ah Codsiyada Warshadaha

Dhammaystirka kor u qaadista waxqabadka, dulqaadka saxda ah ee hooseeya ilaa +/- 0.001", iyo ikhtiyaarrada agabka la xaqiijin karo waxay ka dhigayaan mashiinka CNC tignoolajiyad aad u fiican qaybaha isticmaalka ugu dambeeya. Bilow inaad qaybaha CNC ee gaarka loo leeyahay khadka tooska ah.

Warshadaha Elektaroonigga ah

Warshadaha Caafimaadka

Industry Automotive

Warshadaha beeraha

Warshadaha qalabka mashiinka

Wershadaha hawada

Tel/WeChat:

Tel/WeChat:  E-mail:

E-mail:

Bogga Hore

Bogga Hore