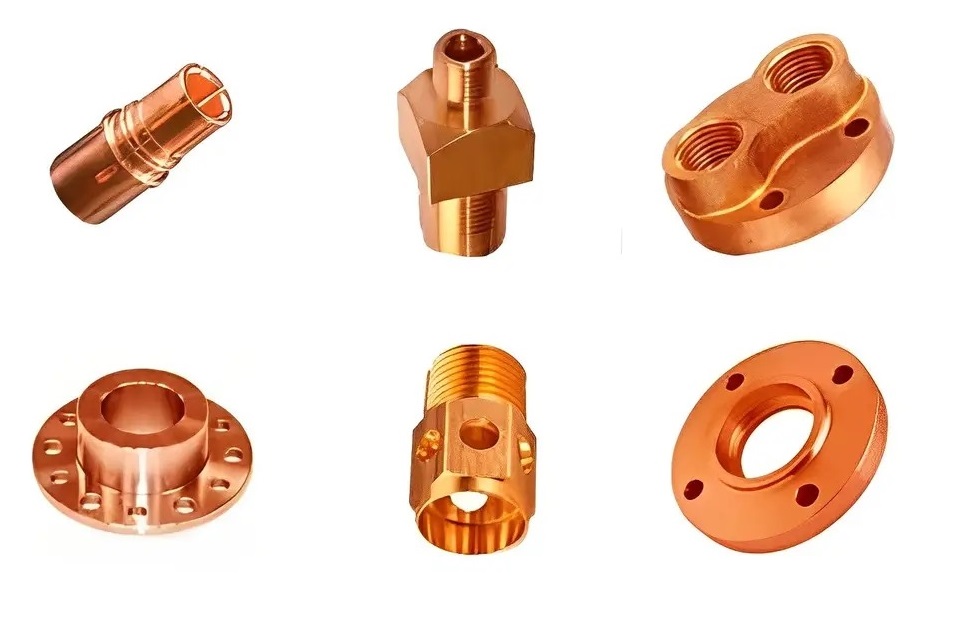

Mashiinka CNC Copper

Naxaasku waa casaan iyo guduud casaan ah ka dib markii filimka oksaydhka laga sameeyay dusha sare, naxaasku waa kan labaad ee lacagta marka loo eego gudbinta korontada iyo gudbinta kulaylka, si weyn ayaa loogu isticmaalaa warshadaha korontada, wax soo saarka matoorada, warshadaha tamarta, propellers-ka maraakiibta, iwm., laakiin xoogga iyo adkaanta ayaa liita.

Waan fahamsanahay in mashruuc kastaa uu yahay mid gaar ah qaybahan naxaasta ahna loo sameeyay si waafaqsan shuruudahaaga. U ogolow injineeradayada mashiinka CNC ee naxaasta ah inay kaa caawiyaan inaad aragtidaada ku farsamayso si sax ah oo xirfad leh.

Mashiinka Naxaasta

Naxaasku aad buu u dhuuban yahay oo dhibic naxaas ah ayaa lagu fidin karaa 2 km oo silig naxaas ah ama lagu riixi karaa sariir bir ah oo naxaas cad ah.

| Codsiyada Shaqaalaha Cusub | Qaybo kala duwan oo gudbinta ah iyo qaybo go'an, sida gacmo-gashi dhululubo ah, isku-xirayaal, dhejisyo, geero, qaybaha qalloocan iyo kuwa rogrogaya, iwm., dhammaantood waxay u baahan yihiin in la sameeyo dahaarka naxaasta ama naxaasta si loo yareeyo xirashada iyo saliidaynta. |

| Faa'iidada | Gudbinta korontada, Gudbinta kulaylka, iska caabbinta daxalka iyo sifooyinka habaynta wanaagsan. |

| Qasaaraha | Qaybaha naxaasta ee CNC ee ku jira deegaanka oo ay ku jiraan walxaha firfircoon ayaa u nugul daxalka. |

| Time Lead | Waqtiga keenista qaybaha nooca prototype waa 1-3 maalmood, wax soo saarka tirada badan wuxuu ku xiran yahay tirada gaarka ah, waxaan haynaa adeegyo farsamayn degdeg ah oo dheeraad ah si loo daboolo baahiyahaaga. |

| Qiimaha | $$$ |

| Dulqaadashada | Waxaa la gaari karaa dulqaad sax ah oo heer sare ah oo ah 0.0004" (0.01mm) |

| Naqshadaynta wax-soo-saarka | Kahor inta aan la farsamayn naxaasta, shuruudaha naqshadeynta iyo qeexitaannada waa in la kala saaraa, taas oo gacan ka geysata shaqeynta qaybaha naxaasta. Kuwaas waxaa ka mid ah yareynta tirada qaybaha la dejiyay, hubinta cabbirka, iyo ka hortagga godadka qoto dheer ee leh raajada yaryar. |

Copper 101

Naxaasta 101 waa naxaas aan ogsijiin lahayn, nadiifnimada naxaasta waa 99.99%, heerka ogsijiintana waa in aan ka badnayn 0.0005%, heerka birta ee u dhigma ee Shiinaha waa naxaasta aan ogsijiinta lahayn ee TU0.

Codsiga: Sixniga kulaylka CPU, shaabadda faakuumka, qaybta transistor-ka, shaabadda birta galaaska, guddiga wareegga daabacan, qalabka isku xirka, iwm.

Codsiga: Sixniga kulaylka CPU, shaabadda faakuumka, qaybta transistor-ka, shaabadda birta galaaska, guddiga wareegga daabacan, qalabka isku xirka, iwm.

Astaamaha: daahirnimo sare, qaab-dhismeed fiican, oksijiin aad u yar, daloolo la'aan, trachoma, dildilaacyo, wasakh, koronto-qaadis heer sare ah.

Astaamaha: daahirnimo sare, qaab-dhismeed fiican, oksijiin aad u yar, daloolo la'aan, trachoma, dildilaacyo, wasakh, koronto-qaadis heer sare ah.

Astaamaha Jirka ee Naxaasta 101

| mugga | Modulus of Elasticity | Saamiga Poisson | Conductivity | Dhaqdhaqaaqa kulaylka | Isku xidhka balaadhinta kulaylka | Dhaqdhaqaaqa Korantada |

| 8.94 g/cm3 | 115 GPA | 0.34 | 58.6 MS/m | 391 W/(mK) | 17.7 10-6/K | 101% IACS |

Sifooyinka farsamada ee naxaasta 101

| State | Xoog siligga | Kordhinta Nasashada (A11.3%) | adkaanta Vickers |

| M 060 | ≥195 | ≥30 | ≤70 |

| Y4 H01 | ≥215-275 | ≥25 | 60-90 |

| Y2 H02 | ≥245-345 | ≥8 | 80-110 |

| Y H04 | ≥295-380 | ≥3 | 90-120 |

| T H06 | ≥350 | ≥110 |

Isku day GreatLight Hadda!

Ma waxaad raadineysaa lammaane lagu kalsoonaan karo oo ku saabsan farsamaynta naxaasta? Laga bilaabo tijaabinta ilaa wax soo saarka, hel natiijooyin aad u wanaagsan mar kasta oo aad isticmaasho adeegyada mashiinka naxaasta ee GreatLight ee CNC ee degdega ah oo hufan!

Copper 102

Copper 102 sidoo kale waxay ka tirsan tahay naxaasta aan ogsijiinta lahayn, daahirnimada naxaastana waa 99.97%, heerka ogsijiintana waa wax aan ka badnayn 0.003%, heerka birta ee u dhigma ee Shiinaha waa naxaasta aan ogsijiinta lahayn ee TU1.

Adeegsiga: qalabka wax lagu beddelo, qalabka wax lagu beddelo iyo qalabka kale ee korontada iyo kuwa lagu beddelo kulaylka, tuubooyinka, qalabka kulaylinta qorraxda sida kuwa loo ururiyo saxannada fidsan iyo qalabka kale ee kulaylka gudbiya.

Adeegsiga: qalabka wax lagu beddelo, qalabka wax lagu beddelo iyo qalabka kale ee korontada iyo kuwa lagu beddelo kulaylka, tuubooyinka, qalabka kulaylinta qorraxda sida kuwa loo ururiyo saxannada fidsan iyo qalabka kale ee kulaylka gudbiya.

Astaamaha Jirka ee Naxaasta 102

| mugga | Modulus of Elasticity | Saamiga Poisson | Conductivity | Dhaqdhaqaaqa kulaylka | Isku xidhka balaadhinta kulaylka | Dhaqdhaqaaqa Korantada |

| 8.94 g/cm3 | 196 GPA | 0.34 | 58.6 MS/m | 391 W/(mK) | 17.7 10-6/K | 100% IACS |

Sifooyinka farsamada ee naxaasta 102

| State | Xoog siligga | Kordhinta Nasashada (A11.3%) | adkaanta Vickers |

| M 060 | ≥205 | ≥20 | ≤80 |

| Y4 H01 | ≥230-290 | ≥15 | 70-100 |

| Y2 H02 | ≥255-350 | ≥5 | 90-120 |

| Y H04 | ≥325-400 | 100-140 | |

| T H06 | ≥370 | ≥120 |

3da siyaabood ee ugu wanaagsan ee lagu shiido naxaasta

Maaddada naxaasta ah waa mid jilicsan, waana ay fududahay in la kululeeyo inta lagu jiro habka shiididda iyadoo la adeegsanayo gudbinta kulaylka degdegga ah, waxayna sidoo kale soo saari doontaa burrs. |

Tel/WeChat:

Tel/WeChat:  E-mail:

E-mail:

Bogga Hore

Bogga Hore