Jaantuska Dhammaadka Dusha: Hagaha Dhamaystiran

Jul 24,2024

Jul 24,2024

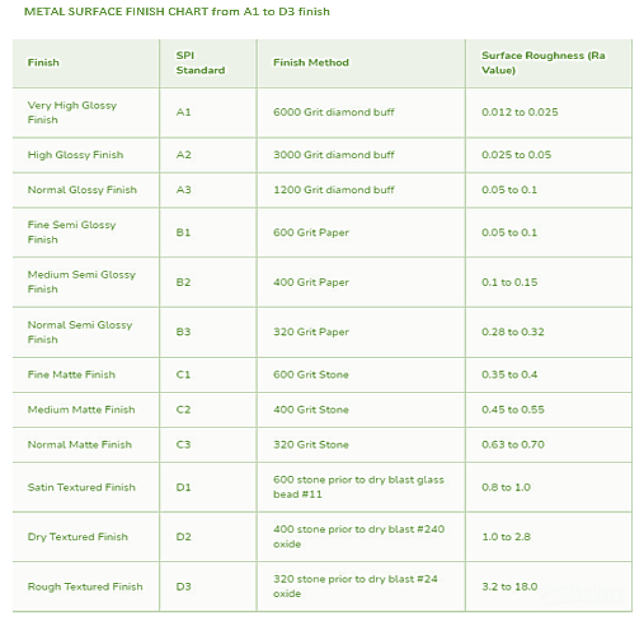

Jaantusyada dhammaadka dusha sare ee biraha waa qalab tixraac ah oo loo isticmaalo hubinta tayada iyo saxnaanta diyaarinta dusha sare. Marka lagu daro sifooyinka jireed sida xoogga, isku-dhafka ama adkeysiga iwm. dusha sare waxay siisaa agabka muuqaal guud. Dhammaystirka dusha sare ee siman wuxuu siinayaa agabka daal iyo iska caabin xirasho oo wanaagsan. Qafiifnimo ayaa loo baahan yahay si loo mariyo dahaarka iyo marka loo baahdo is-jiidjiid.

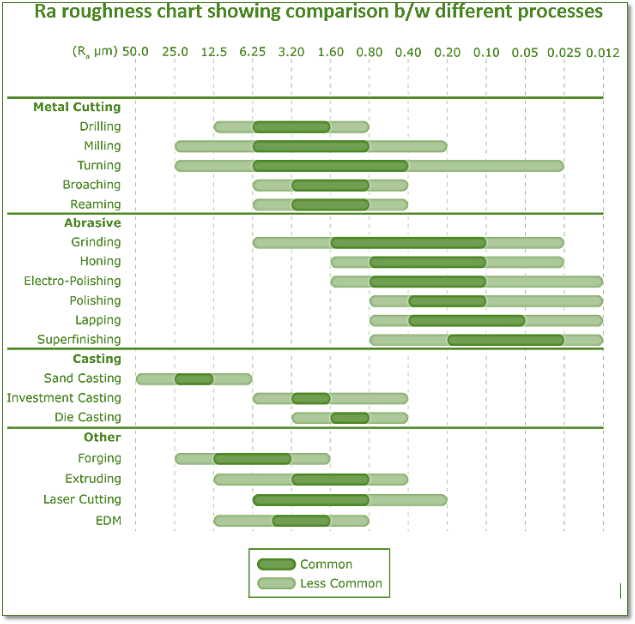

Shaxda dhammaynta dusha sare waxay kaa caawin doontaa inaad doorato habka ugu habboon uguna kharash badan ee jilicsanaanta la rabo. Halkan, maqaalkan, jaantus dhammaystiran oo kala duwan ayaa muujinaya isbarbardhigga qallafsanaanta dusha sare ee hababka, qalabka iyo cabbirrada.

Dhammaadka Dusha Sare: Dulmar Guud

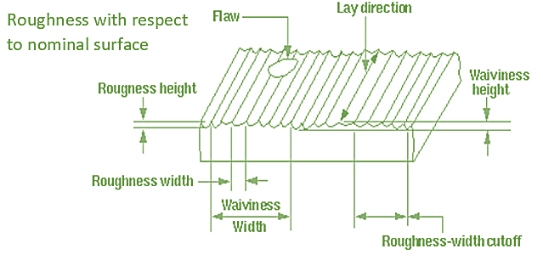

Dhammaystirka dusha sare waxaa sidoo kale lagu qeexaa qaab-dhismeedka dusha sare ama qaab-dhismeedka dusha sare, wuxuuna kuu sheegayaa dabeecadda dusha sare iyada oo loo marayo astaamahan qallafsanaanta dusha sare, jiifitaanka iyo leexashada. Qodobbada muhiimka ah sida iska caabbinta xirashada, is-xoqidda iyo dhegdheg waxaa saameeya dhammaystirka dusha sare ee badeecada.

Muhiimadda Shaxda Dhammaystirka Dusha Sare ee Wax Soo Saarka iyo Injineerinka

Jaantusyada dhammaadka dusha sare waxaa loo isticmaalaa in lagu muujiyo celceliska qallafsanaanta walax gaar ah ka dib farsamooyin kala duwan oo farsamayn ah sida, shiididda, dhalaalinta iyo xoqidda. Markaan eegno jaantusyadan waxaan si xikmad leh u dooran karnaa agabka iyo habka loo farsameeyo si loo helo qallafsanaanta dusha sare ee la rabo.

Dhammaystirka dusha sare wuxuu ku siinayaa faa'iidooyin sida kordhinta waxqabadka, cimri dhererka iyo iska caabbinta daxalka. Waxaan sidoo kale kordhin karnaa qabashada oo yareyn karnaa dhalaalka annagoo samaynayna dusha sare oo qaabaysan.

Iyada oo leh faa'iidooyin badan, waxay sidoo kale leedahay qaar ka mid ah khasaarooyinka sida kordhinta kharashka farsamaynta. Waxay yareysaa xoogga walxaha iyadoo laga saarayo lakabka ugu sarreeya. Dusha sare ee qallafsan waxay sababi kartaa walxaha u nugul daxalka sababtoo ah baaxadda dusha sare ee korodhay.

Marka laga soo tago xulashada habka, jaantusyadani waxay sidoo kale wanaajiyaan habka waxayna kordhiyaan waxtarka kharashka. Dhammaystirka dusha sare waxaa loo habeeyey si waafaqsan hab caadi ah, taas oo sidoo kale ka caawisa ilaalinta tayada badeecada.

Sida loo cabbiro dhammaadka dusha sare

Farsamooyinka cabbiraadda dusha sare waxaa loo kala saaraa laba qaybood oo ballaaran oo hababka isbarbardhigga dusha sare ama hababka aan taabashada lahayn. Farsamooyinka caadiga ah ee loo isticmaalo cabbiraadda qallafsanaanta dusha sare waa.

Muuqaalka dusha sare

Sawirka dusha sare ee sawirka waxaa lagu sameeyaa cabbiraadda qallafsanaanta iyo dhumucda filimka. Farsamadan, stylus-ka cidhifka dheeman ayaa lagu dul dhaqaajiyaa dusha sare ee muunadda.

Kormeerka xoqidda

Farsamadan kormeerka waxay u baahan tahay walxo jilicsan oo lagu raro dusha sare ee muunadda waxayna muujinaysaa qaabka xoqidda ee dusha sare. Agab sida rasaasta Babbitt ama balaastig ayaa la isticmaalaa.

Sawirro yar yar

Muunadda waxaa la dhigayaa mikroskoobka hoostiisa, sawirradeedana waxaa la barbar dhigayaa sawirrada dhammaadka dusha sare ee loo baahan yahay.

Baadhitaan muuqaal ah

Haddii qallafsanaanta dusha sare ay leedahay qiimo sare, si muuqaal ah ayaa loo arki karaa oo loo tijaabin karaa. Kormeerkani wuxuu leeyahay saxnaan xaddidan. Haddii qallafsanaanta ay yaraato, magnifiers-ka iftiinka leh ayaa looga baahan yahay shaqada.

Induction

Cabbirka qallafsanaanta dusha sare ee dijitaalka ah wuxuu soo saaraa calaamadaha wax soo saarka iyada oo loo marayo isbeddelka ku yimaada inductance-ka gariiradaha marka baaruhu uu ku socdo dusha sare ee qallafsan.

Sawirka leysarka

Microscope-yada laysarka ee confocal-ka ah ayaa loo isticmaalaa habkan. Waxay ku shaqeeyaan laba qaab oo xiriir ah iyo qaab aan xiriir lahayn. Microscope-yadani waxay ku siinayaan cabbiraadda dhidibka toosan waxayna sidoo kale samayn karaan cabbir 3D ah iyagoo adeegsanaya sawirro fog.

Baaritaanka Ultrasonic

Dareemayaasha Ultrasonic-ka ayaa sidoo kale loo isticmaali karaa in lagu cabbiro qallafsanaanta dusha sare. Isbeddelka dhacdada iyo hirarka dhawaaqa ee ka muuqda waxaa sabab u ah qaab-dhismeedka dusha sare kaas oo ku siinaya qiimayaasha cabbirka.

Kala soocida Shaxda Dhamaystirka Dusha Sare

Dhammaystirka dusha sare waxaa loo kala saaraa qaybaha soo socda;

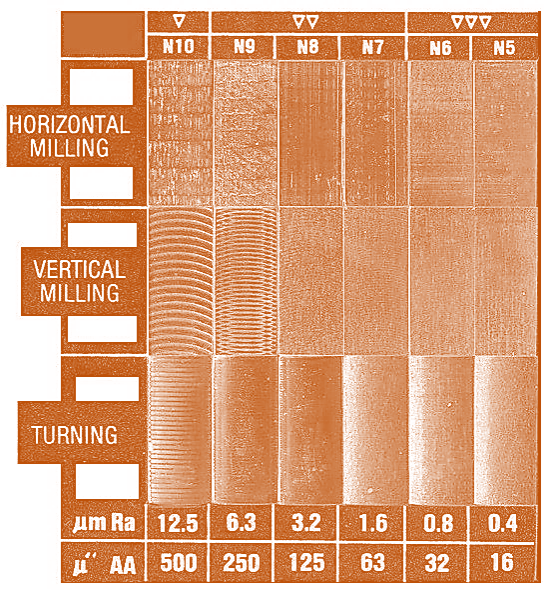

Shaxda dhammaystirka dusha mashiinka

Hawsha mashiinka sida shiididda, shiididda, leexinta ama qodista waxay soo saartaa qallafsanaan dusha sare ah oo kala duwan ka dib marka la farsameeyo. Shaxda dhammaadka dusha sare ee mashiinka waxay ku siinaysaa isbarbardhigga qallafsanaanta dusha sare ee celceliska ah ee ay soo saarto hab kasta oo mashiinka lagu farsameeyo. Tani waxay kaa caawin doontaa inaad doorato habka ku siinaya qallafsanaanta la rabo.

|

Shahaadada Dhammaadka (Shiinaha)

|

ra (um) |

rz (um) |

ra (micro inji) |

Habka Dhammaystirka Mashiinka |

|

1 |

50 |

200 |

2000 |

Ku shubista qallafsan ama mashiinada ugu adag |

|

2 |

25 |

100 |

1000 |

Wareejin qallafsan, caajis, qorsheyn, qodis. Calaamadaha mashiinka ayaa iska cad |

|

3 |

12.5 |

50 |

500 |

La mid ah dhammaystirka 2-degree |

|

4 |

6.3 |

25 |

320 |

Wareeg caadi ah, caajis, qorsheyn, qodid, shiidi. Calaamaduhu way muuqdaan |

|

250 |

||||

|

5 |

3.2 |

12.5 |

200 |

Habab isku mid ah sida 4 darajo laakiin calaamadaha mashiinka ayaa si yar u muuqda |

|

160 |

||||

|

125 |

||||

|

6 |

1.6 |

6.3 |

100 |

Hawshani waxaa loo isticmaalaa: leexashada la xakameeyey ee tirada, caajiska, qorsheynta, qodista, shiididda. Calaamadaha mishiinku ma muuqdaan laakiin tilmaamaha waa |

|

80 |

||||

|

63 |

||||

|

7 |

0.8 |

6.3 |

50 |

Habab isku mid ah sida dhammaadka shahaadada 6. Laakiin jihooyinka waa kuwo aan caddayn |

|

40 |

||||

|

32 |

||||

|

8 |

0.4 |

3.2 |

25 |

Hawsha sida Dib-u-habaynta, shiididda, caajiska, rogidda ayaa dusha sare ka dhigaysa mid siman laakiin jihada calaamaduhu waa mid aan caddayn |

|

20 |

||||

|

16 |

||||

|

9 |

0.2 |

1.6 |

12.5 |

Shiidida, farsamaynta aadka u sarreysa waxay ka dhigtaa calaamadaha iyo jihadooda mid aan la arki karin |

|

10 |

||||

|

8 |

||||

|

10 |

0.1 |

0.8 |

4 |

Makiinadaha super dheeraad ah waxay soo saartaa dhammaystirka ugu sarreeya ee dusha sare ee dhalaalaya madow |

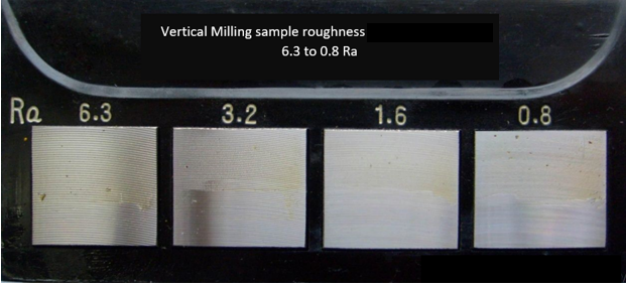

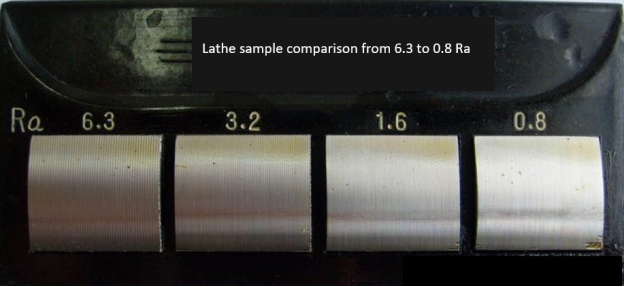

Dhammaystirka dusha sare iyo tirada qallafsanaanta muunadaha iyada oo loo marayo geeddi-socod kala duwan oo ah milling toosan, rogidda iyo milling toosan ayaa lagu barbar dhigay jaantuska hoose.

Shaybaaradani waxay leeyihiin qaabab kala duwan oo dusha sare ah sababtoo ah qalab kala duwan oo wax lagu farsameeyo, haddana waxay ku jiraan tiro isku mid ah oo qallafsanaan ah sababtoo ah celcelis ahaan qallafsanaantoodu waa isku mid.

Shaxda dhammaadka dusha sare ee warshadaynta

Si ka duwan jaantuska dusha sare ee mashiinka, diiradda ugu weyn ee jaantuska dusha sare ee mashiinka ayaa ah habka mashiinka. Waxay isbarbar dhigaysaa celceliska qallafsanaanta dusha sare ee ay soo saaraan qalabka jarista ee kala duwan, xawaaraha jarista iyo heerarka quudinta. Markaa, haddii lagu siiyo oo keliya doorashada habka mashiinka mashiinka, adoo eegaya jaantuskan dhammaadka dusha sare waxaad hagaajin kartaa habka.

Shaxda dhammaadka dusha sare ee lathe

Jaantuska dhammaadka dusha sare ee lathe wuxuu muujinayaa kala duwanaanshaha qallafsanaanta dusha sare ee ka dhalatay agabyo kala duwan iyo xuduudaha jarista. Haddii aad tahay mashiin ama injineer jaantusyadani waxay kaa caawin doonaan inaad doorato dejimaha lathe-ga ugu fiican si aad u hesho qaab-dhismeedka la rabo ee dusha sare ee walxo gaar ah.

Shaxda dhammaystirka dusha sare ee balaastikada ah

Shaxda dhammaystirka balaastikada ah waxay ku siinaysaa farqiga u dhexeeya dhammaystirka kala duwan, baaxadda qallafsanaantooda iyo kharashka lagu gaarayo dhammaystirka. Kadib walxaha balaastikada ah ayaa la barbar dhigayaa qallafsanaanta la rabo, tusaale ahaan walxaha ugu habboon ee dusha sare ee dhalaalaya ee A1 (oo leh qallafsanaan ugu yar) waa polymer acrylic ah. Polypropylene iyo Polyurethane kuma habboona dhammaystirka dusha sare ee dhalaalaya.

Balaastigyo kala duwan iyo ku habboonaantooda dusha sare ee A1, A2 iyo A3 ayaa la bixiyay.

|

Polymers |

A1 |

A2 |

A3 |

|

ABS |

Celceliska |

Celceliska |

Good |

|

Polypropylene (PP) |

Poor |

Celceliska |

Celceliska |

|

Polystyrene (PS) |

Celceliska |

Celceliska |

Good |

|

HDPE |

Poor |

Celceliska |

Celceliska |

|

nylon |

Celceliska |

Celceliska |

Good |

|

Polycarbonate (PC) |

Celceliska |

Good |

aad u fiican |

|

Polyurethane (TPU) |

Poor |

Poor |

Poor |

|

looxa |

aad u fiican |

aad u fiican |

aad u fiican |

Shaxda dhammaadka dusha sare ee birta

Shaxda dhammaadka dusha sare ee biraha waxay bixisaa isbarbardhig isku dhafan oo u dhexeeya qallafsanaanta dusha sare ee biraha kala duwan ka dib marka la isticmaalo hababka kala duwan ee mishiinka sida shiididda, shiididda iwm. Waxay sidoo kale ka caawisaa hagaajinta. Jaantusyadani waxay wax badan ka sheegayaan hababka dhammaystirka ee la xiriira agabka si ka duwan jaantusyada mishiinka kaas oo bixiya isbarbardhigga dhammaan hababka mishiinka.

Shaxda dhammaystirka dusha sare ee birta aan daxalka lahayn

Shaxda dhammaystirka dusha sare ee birta aan miridhku lahayn waxay ku tusaysaa celceliska qallafsanaanta, jajabka iyo tirada dhalaalka. Tirada jajabka iyo dhalaalku waxay ku salaysan yihiin habka agabkayaga loo isticmaalo bixinta dhammaystirka dusha sare. Tirada boolisku waxay u dhaxaysaa 1 ilaa 8, 1 lama safayn iyo 8th waxay leedahay lambarka ugu hooseeya ee qallafsanaanta. Dhammaystirka dusha sare waxaa lagu sameeyaa giraangiraha xarigga ah oo leh lakab walxo xoqan oo leh tiro gaar ah oo ciid ah.

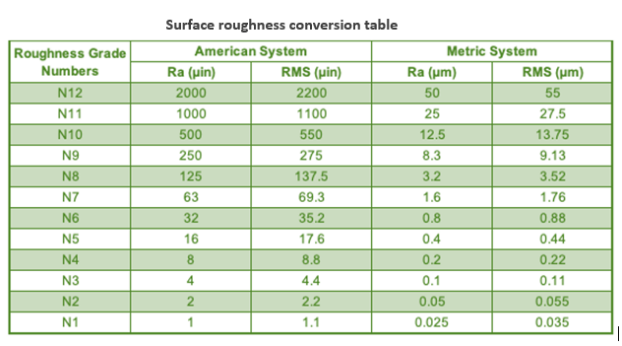

Shaxda beddelka dhammaystirka dusha sare

Warshado kala duwan ayaa isticmaala cutubyo kala duwan oo siman oo ah qallafsanaanta dusha sare. Shaxdani waxay kaa caawin doontaa inaad fahamto jaantusyada dhammaadka dusha sare ee ay isticmaalaan warshadaha kala duwan ee dalalka kale. Isku beddelka cutubyada soo socda ayaa la sameeyaa:

Ra = Celceliska qallafsanaanta ee micrometers ama microinches.

RMS = Afargeesle Celcelis ah oo ku jira hal inji.

CLA = Celceliska Khadka Dhexe ee microinches.

Rt = Wadarta qallafsanaanta ee makron

N = Tirooyinka miisaanka ISO (darajada) cusub.

Dhererka Goynta = Dhererka looga baahan yahay muunadda.

|

N |

Ra |

Rz |

CLA |

RMS |

Dhererka jarista |

|

|

Cirbado |

mm |

|||||

|

1 |

0.3 |

0.025 |

1 |

1.1 |

0.003 |

0.08 |

|

2 |

0.5 |

0.05 |

2 |

2.2 |

0.01 |

0.25 |

|

3 |

0.8 |

0.1 |

4 |

4.4 |

0.01 |

0.25 |

|

4 |

1.2 |

0.2 |

8 |

8.8 |

0.01 |

0.25 |

|

5 |

2.0 |

0.4 |

16 |

17.6 |

0.01 |

0.25 |

|

6 |

4.0 |

0.2 |

32 |

35.2 |

0.03 |

0.8 |

|

7 |

8.0 |

1.6 |

63 |

64.3 |

0.03 |

0.8 |

|

8 |

13 |

3.2 |

125 |

137.5 |

0.1 |

2.5 |

|

9 |

25 |

6.3 |

250 |

275 |

0.1 |

2.5 |

|

10 |

50 |

12.5 |

500 |

550 |

0.1 |

2.5 |

|

11 |

100 |

25 |

1000 |

1100 |

0.3 |

8.0 |

Fahmidda Noocyada Kala Duwan ee Shaxda Dhammaystirka Dusha Sare

Shaxda dhammaadka dusha sare ee qaraxa kuul

Kubbadaha lagu qarxiyo waxaa lagu sameeyaa iyadoo la beegsanayo kuul galaas ama bir ah cadaadis sare oo saaran dusha sare ee walxaha la diyaarinayo. Waxay bixisaa celcelis ahaan qallafsanaan ah 42 Ra (micro-inji). Shaxda caadiga ah ee kubbadaha ayaa ku siinaysa isbarbardhigga qiimayaasha qallafsanaanta iyadoo la adeegsanayo cabbirro iyo agabyo kala duwan oo kubbadaha ah. Masaafada cadaadiska iyo afka ayaa sidoo kale lagu dari karaa jaantuska si loo wanaajiyo dhammaystirka dusha sare.

|

Fasalka |

Neefsashada Dhulka |

Imaanshaha |

Codsiyada |

|

Fasalka 1 |

Kuul aad u Fiican |

Dabacsan |

Qaybaha qurxinta, qalabka caafimaadka |

|

Fasalka 2 |

Qarax Fiican |

Qaab-dhismeed Hoose |

Qaybaha Aerospace |

|

Fasalka 3 |

Qarax Dhexdhexaad ah |

Qaab-dhismeed Dhexdhexaad ah |

Qaybaha baabuurta, Makiinado |

|

Fasalka 4 |

Qarax qaro weyn |

Qoraal qallafsan |

Qaybaha badda |

Shaxda Dhumucda Dahaadhka

Shaxdani waxay kugula talinaysaa dhumucda dahaadhka ama noocyada kala duwan ee la rabo ee ku yaal walxo gaar ah. Dhumucda dahaadhka waxaa lagu muujiyaa cutubyo badan sida micrometers, milimitir, mils (kumanaan inji) ama microinch. Markaa, haddii aad u baahan tahay inaad dahaadhka ku mariso cutubyo kala duwan, markaa jaantuskani wuxuu kuu badbaadin doonaa waqtigaaga [15]. Jaantusyadani waxay muhiim u yihiin warshadaha sida rinjiga, ilaalinta daxalka, xakamaynta tayada iwm. [14].

|

umm |

mm |

inch |

mil (kun) inji ah) |

Toban meelood (ee inji ah)

|

Milyan (hal) Milyan inji ah) |

|

1 |

0.1 |

0.0001 |

0.000004 |

0.004 |

0.04 |

|

2 |

0.5 |

0.0005 |

0.00002 |

0.02 |

0.2 |

|

3 |

1 |

0.001 |

0.000039 |

0.039 |

0.39 |

|

4 |

1.5 |

0.0015 |

0.000059 |

0.059 |

0.59 |

|

5 |

2 |

0.002 |

0.000079 |

0.079 |

0.79 |

|

6 |

2.5 |

0.0025 |

0.000098 |

0.098 |

0.98 |

|

7 |

3 |

0.003 |

0.000118 |

0.118 |

1.18 |

|

8 |

3.5 |

0.0035 |

0.000138 |

0.138 |

1.38 |

|

9 |

4 |

0.004 |

0.000157 |

0.157 |

1.57 |

|

10 |

4.5 |

0.0045 |

0.000177 |

0.177 |

1.77 |

|

11 |

5 |

0.005 |

0.000197 |

0.197 |

1.97 |

|

12 |

5.5 |

0.0055 |

0.000217 |

0.217 |

2.17 |

|

13 |

6 |

0.006 |

0.000236 |

0.236 |

2.36 |

|

14 |

7 |

0.007 |

0.000276 |

0.276 |

2.76 |

|

15 |

8 |

0.008 |

0.000315 |

0.315 |

3.15 |

|

16 |

9 |

0.009 |

0.000354 |

0.354 |

3.54 |

|

17 |

10 |

0.01 |

0.000394 |

0.394 |

393.7 |

|

18 |

12 |

0.012 |

0.000472 |

0.472 |

4.72 |

|

19 |

15 |

0.015 |

0.000591 |

0.591 |

5.91 |

|

20 |

20 |

0.02 |

0.000787 |

0.787 |

7.87 |

Shaxda Tayada Dhammaystirka

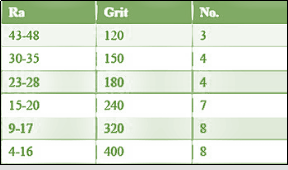

Shaxda tayada dhammaystirka waxay ku tusinaysaa noocyo kala duwan oo dhammaystir dusha sare ah laga bilaabo dusha aan la safayn ilaa dusha sare ee dhalaalaysa (oo aad u milicsan) iyo qiimahooda qallafsanaanta dusha sare ee micrometer (µm) ama microinches (µin). Kuwani mararka qaarkood waxay ka kooban yihiin sawirro dusha sare ee agabka dhammaystirka ah. Shaxda soo socota waxay leedahay tirooyin darajo iyo calaamado kala duwan oo loogu talagalay lambarrada qallafsanaanta.

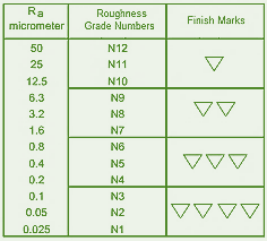

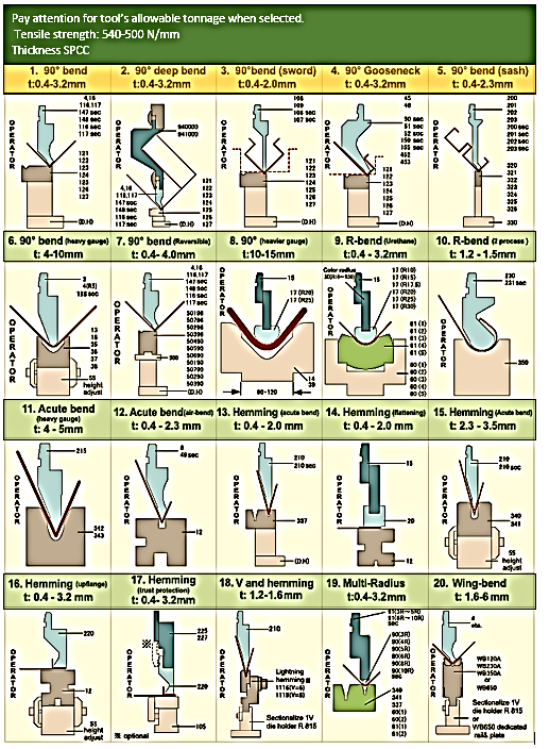

Shaxda Qalabka

Shaxda qalabka waxay ku siinaysaa macluumaad ku saabsan dhowr qalab oo loo isticmaalo warshadaha. Qaybaheeda ugu muhiimsan waa nooca qalabka, cabbirka qalabka, heerka quudinta ama agabka [16]. Waxay kordhisaa hufnaanta habka waxayna sidoo kale yareysaa khasaaraha agabka iyadoo la adeegsanayo qalabka saxda ah ee shaqada. Markaa, waxay kuu badbaadin doontaa lacag iyo waqti.

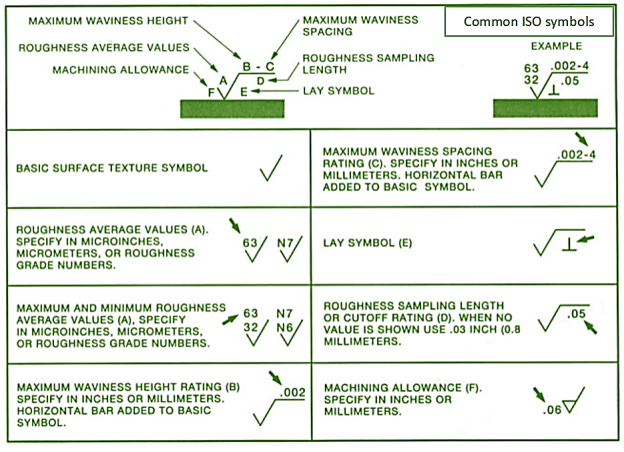

Shaxda calaamadaha dhammaadka dusha sare

Calaamadaha dhammaadka dusha sare ee ISO

Shaxda qallafsanaanta Ra

ra waa qiimaha celceliska qallafsanaanta waxaa loo isticmaalaa in lagu cabbiro celceliska leexashada caadiga ah ee xariiqda celceliska. Waxaa lagu matali karaa marka loo eego µm ama µin. Waxa kale oo ay soo bandhigaysaa dhammaystirka dusha sare oo ay weheliso qiimaha qallafsanaanta ra. Markaad eegto celceliska qallafsanaanta dhammaadka dusha sare waxaad dooran kartaa agab u baahan khilaaf gaar ah, awoodaha shaabadaynta iyo muuqaalka bilicda.

Shaxda qallafsanaanta dusha sare ee Rz

rz waxaa loo yaqaan qallafsanaanta qoto dheer. Waxaa lagu xisaabiyaa iyadoo la helayo masaafada celceliska ah ee u dhaxaysa meesha ugu sarreysa iyo meesha ugu hooseysa. Jaantuska qallafsanaanta dusha sare ee rz sidoo kale wuxuu soo bandhigayaa dusha sare ee kala duwan oo qaabaysan oo ay weheliso qiimayaasha rz. Waxay kuu sheegaysaa iska caabbinta xirashada walxaha iyo sida ay u qaban karto saliid.

|

Shahaadada Dhammaadka

|

rz (um) |

Habka Dhammaystirka Mashiinka |

|

N12 |

200 |

Ku shubista qallafsan ama mashiinada ugu adag |

|

N11 |

100 |

Wareejin qallafsan, caajis, qorsheyn, qodis. Calaamadaha mashiinka ayaa iska cad |

|

N10 |

50 |

La mid ah dhammaystirka 2-degree |

|

N9 |

25 |

Wareeg caadi ah, caajis, qorsheyn, qodid, shiidi. Calaamaduhu way muuqdaan |

|

N8 |

12.5 |

Habab isku mid ah sida 4 darajo laakiin calaamadaha mashiinka ayaa si yar u muuqda |

Shaxda dhammaadka dusha sare ee rms

Dhammaadka dusha sare ee rms, qallafsanaanta dusha sare ee chat waxaa lagu muujiyaa rms (xidid celcelis ahaan afargeesle). Waxay leedahay cutubyo la mid ah µm ama µin. Jaantuskani wuxuu sidoo kale bixiyaa fikrad ku saabsan nolosha daalka maadiga ah.

|

Shahaadada Dhammaadka

|

rms |

Habka Dhammaystirka Mashiinka |

|

N12 |

55 |

Ku shubista qallafsan ama mashiinada ugu adag |

|

N11 |

27.5 |

Wareejin qallafsan, caajis, qorsheyn, qodis. Calaamadaha mashiinka ayaa iska cad |

|

N10 |

13.75 |

La mid ah dhammaystirka 2-degree |

|

N9 |

9.13 |

Wareeg caadi ah, caajis, qorsheyn, qodid, shiidi. Calaamaduhu way muuqdaan |

|

N8 |

3.52 |

Habab isku mid ah sida 4 darajo laakiin calaamadaha mashiinka ayaa si yar u muuqda |

beddelka jaantuska qallafsanaanta dusha sare

Jaantuskani wuxuu u beddelaa qallafsanaanta dusha sare cutubyo badan. Tani waxay kaa caawineysaa inaad doorato cutubka caadiga ah ee warshaduhu isticmaalayaan. Qaacidooyinka soo socda ayaa loo isticmaalaa in lagu beddelo cutubyadan.

- Mikromitir (µm) ilaa Mikromitir (µin): Mikromitir (µin) = Mikromitir (µm) x 39.3701

- Mikromitir (µm) ilaa Milimitir (mm): Milimitir (mm) = Mikromitir (µm) / 1000

- Microinji (µin) ilaa Micrometers (µm): Micrometers (µm) = Microinji (µin) / 39.3701

- Microinches (µin) ilaa Millimeters (mm): Millimeters (mm) = Microinches (µin) / 39,370

- Millimeter (mm) ilaa Micrometers (µm): Micrometers (µm) = Millimeter (mm) x 1000

- Millimeter (mm) ilaa Microinches (µin): Microinches (µin) = Millimeter (mm) x 39,370

Shaxda tusaale ahaan waxaa lagu bixiyay hoos shaxda beddelka qallafsanaanta dusha sare [1].

Waxyaabaha Saameynaya Dhammaadka Dusha Sare

Qaar ka mid ah arrimaha ugu muhiimsan ee ay tahay inaad maskaxda ku hayso waa;

Qalabka Jarida

Nooca qalabka jarista ee aad isticmaaleyso wuxuu sidoo kale saameeyaa qallafsanaanta dusha sare, tusaale ahaan qalabka birta ee xawaaraha sare leh wuxuu soo saaraa qallafsanaan badan dusha sare halka qalabka carbide iyo dhoobada ay ku siinayaan dusha siman.

Qalafsanaanta maaddada

Haddii adkaysiga agabku uu u dhow yahay adkaanta qalabka jarista, qallafsanaanta dusha sare way ka sarreyn lahayd. Sidaas ayay u sii weynaan lahayd farqiga adag ee u dhexeeya laba walxood, dusha sarena way simanaan lahayd.

Qiyaasaha mashiinka

Xuduudaha mashiinka sida xawaaraha jarista, qoto dheer ee jarista, quudinta iyo heerka lagu saarayo walxaha. Xuduudahaan waxaa loo beddeli karaa inay yeeshaan qallafsanaan dusha sare ah oo la rabo.

Saliidaynta iyo qaboojinta

Saliidaynta ama hababka kale ee qaboojinta waxay yareeyaan is jiidjiidka waxayna sidoo kale ka badbaadiyaan qalabka waxyeelada waxayna bixiyaan dhammaystir dusha sare oo nadiif ah.

Daawaynta kadib warshadaynta

Ka dib marka la farsameeyo habayn dheeraad ah sida daaweynta kiimikada, shiididda iyo nadiifinta ayaa la sameeyaa si loo kordhiyo simanaanta dusha sare.

Shaxda Jaantuska Beddelka Qalafsanaanta Dusha Sare

Jadwalka soo socda wuxuu muujinayaa beddelka qallafsanaanta cutubyo kala duwan.

Dhammaadka dusha sare waxaa lagu hubiyaa

Dhammaystirka dusha sare waxaa lagu hubiyaa mitirrada profilometer-ka iyo farsamooyin kala duwan oo kor lagu sheegay. Mitirrada profilometer-ku waxay ka kooban yihiin qalin-qoraal oo dul mara dusha sare ee maaddada isla markaana xisaabiya qoto dheeraanta qallafsanaanta.

Ugu Dambeyn

Dhammaystirka dusha sare looma sameeyo oo keliya in badeecaddu ka dhigto mid bilic leh. Dhammaystirka dusha sare ee wanaagsan wuxuu hagaajin karaa iska caabbinta daalka agabka. Noocyo badan oo jaantusyada dhammaadka dusha sare ah ayaa lagu falanqeeyay maqaalkan kaas oo ku siinaya fikrad ku saabsan kala duwanaanshaha qallafsanaanta dusha sare ee laga helo noocyada iyo qalabka kala duwan ee wax lagu farsameeyo.

Jaantusyada dhammaadka dusha sare waxay kuu badbaadinayaan waqtigaaga inaad hesho habka ugu sarreeya iyo qalabka loogu talagalay qallafsanaanta dusha sare ee la rabo. Siyaabaha lagu xisaabiyo qallafsanaanta dusha sare ayaa sidoo kale lagu daray kuwaas oo kaa caawin doona sameynta jaantusyada. Waxaad samayn kartaa jaantusyo gaar ah iyadoo loo eegayo baahidaada adoo isticmaalaya cutubyada caadiga ah.

Wixii waxbarasho dheeraad ah iyo sahaminta, waxaad ka hubin kartaa ururka caalamiga ah ee heerarka (ISO). Waxaa jira heerar la xiriira qallafsanaanta dusha sare iyo xisaabinta qaab-dhismeedka sida ISO 4287, ISO 25178, iyo ISO 1302. Waxaad ka hubin kartaa koorsooyinka khadka tooska ah ee ku saabsan Udemy iyo Coursera, sidoo kale waxaa jira waraaqo cilmi baaris iyo buugaag badan oo lagu baran karo qaybtan.

Khubarada Shiinaha ee GreatLight CNC ayaa sidoo kale ku siinaya qalabka dhammaystirka dusha sare. Waxaa loo qaybiyaa laba nooc, mid waxaa lagu gaaraa iyadoo laga saarayo walxaha kan kalena waxaa lagu sameeyaa iyadoo lagu darayo lakab dahaadh ah. Hababkan soo socda ayaa la isticmaalaa:

- Burburinta Usha

- Caadinta

- Qalabka korantada

- Cabbiraadda budada

- qiraan

- caday

- Oksaydhka madow

- Alodine

- Qayb sameynta

FAQs

Alxanka ma habka loo isticmaalo in lagu gaaro dhammaadka dusha sare?

Maya, alxanka looma sameeyo ujeeddada lagu gaarayo dhammaystirka dusha sare. Alxanku waa hab isku xidh ah oo laba bir ah la isku daro. Dhammaystirka dusha sare waa natiijada habab kala duwan sida shiididda, nadiifinta, ama dahaarka. Alxanku wuxuu ku jiri karaa dusha sare ee birta ama dahaarka laakiin macnaheedu maahan in loo isticmaalo ujeeddadaas.

Waa maxay dhammaystirka dusha sare ee 125-ka ah?

Dhammaystirka dusha sare ee 125-ka ah wuxuu qeexayaa in dusha sare loo farsameeyay si loo gaaro celcelis ahaan qiime qallafsanaan ah oo ah 125 microinches (µin) ama qiyaastii 3.2 micrometers (µm). Dhammaystirkani wuxuu la xiriiraa dusha siman ee saxda ah ee loogu talagalay codsiyada injineernimada gaarka ah.

Dhammaystirka dusha sare ee tayada fiican ayaa laga soo saaraa?

Tel/WeChat:

Tel/WeChat:  E-mail:

E-mail:

Bogga Hore

Bogga Hore

Aluminium 6061 T6 vs T651 vs T6511: Waa maxay faraqa?

Aluminium 6061 T6 vs T651 vs T6511: Waa maxay faraqa?