EDM Machining Working Principle: 3 Types and Applications

Aug 30,2024

Aug 30,2024

Electrical Discharge Machining (EDM) is a precise technique used to shape materials using electrical sparks. This guide will explain how EDM works, the materials it can machine, the types of EDM machines, and their specific benefits.

What is EDM Machining?

Qeexid iyo dulmar

EDM machining uses electrical discharges (sparks) to remove material from a workpiece. This method is non-contact, making it ideal for machining hard metals. EDM machines can achieve precision as high as ±0.005 mm, which is crucial for high-tolerance applications.

Simple Overview Table

| feature | Description |

|---|---|

| Habka | Uses electrical discharges (sparks) |

| Ka saarida walxaha | Material is vaporized and melted by sparks |

| sax | ± 0.005 mm |

| Ugu fiican | Hard, electrically conductive materials |

Isku day GreatLight Hadda!

Xalalka gaarka ah ee naqshadaha adag: u dir sawirro [emailka waa la ilaaliyay]

Oraahyada dhabta ah ee aadanaha ayaa ka saxsan xigashooyinka software-ka

How EDM Machining Works

The Principle of Electrical Discharge Machining

EDM works by generating a spark between an electrode and the material. The spark temperature can reach up to 12,000°C, which is high enough to melt and vaporize tiny parts of the material. Below is a simplified chart to illustrate the process:

| Electrode (Tool) | Spark (12,000°C) | Ka saarida walxaha |

| Electrical energy is supplied to the electrode. | A spark jumps across the gap, generating intense heat. | The material melts and vaporizes, removing small amounts of it. |

Basic Mechanism and Material Removal Process

- Talaabada 1: The electrode moves close to the material, usually with a gap of 0.01-0.05 mm.

- Talaabada 2: A spark jumps from the electrode to the material.

- Talaabada 3: The spark melts and removes a small piece of the material.

- Talaabada 4: The removed material is washed away by a dielectric fluid.

Simple EDM Process Flowchart

This flowchart outlines the basic steps of the EDM process, from positioning the electrode to flushing away debris.

| Position Electrode | Spark Generation (12,000 ° C) |

Ka saarida walxaha | Flush Away Debris |

| Electrode is positioned close to the workpiece. | Spark generates intense heat (12,000°C). | Material melts and is removed. | Debris is flushed away by dielectric fluid. |

Materials Suitable for EDM Machining

Agabka caadiga ah

EDM is particularly suitable for machining hard metals that conduct electricity. Below are some examples of materials and their typical applications:

| Waxyaabaha | Isticmaalka caadiga ah | Dhaqanka (S/m) | Hardness (HRC) |

|---|---|---|---|

| Birta adag | Mold making, precision tools | 1 x 106 | 50-60 HRC |

| Carbide | Cutting tools, wear parts | 2.3 x 106 | 85-90 HRC |

| titanium | Aerospace parts, medical devices | 2.38 x 106 | 36 HRC |

Material Properties That Affect EDM Performance

Certain material properties can affect the efficiency and effectiveness of EDM machining. These properties include:

- Waxqabadka Korontada: Materials must have a conductivity greater than 1 x 106 S/m

- Saabsanaanta: Harder materials (above 50 HRC) are generally easier to machine with EDM.

- Dabaalidda: Materials with high melting points (above 1,500°C) may require longer machining times.

Types of EDM Machining

Siliga Goynta EDM

Siliga Goynta EDM uses a thin wire, typically 0.25 mm in diameter, as the electrode to cut through the material. This method is used to create intricate shapes with high precision.

Codsiyada iyo Faa'iidooyinka

- Waxaa loo isticmaalaa: Cutting complex shapes, making tools, and dies.

- Faa'iidooyinka: High precision (±0.01 mm), can cut materials up to 300 mm thick.

Hooska EDM

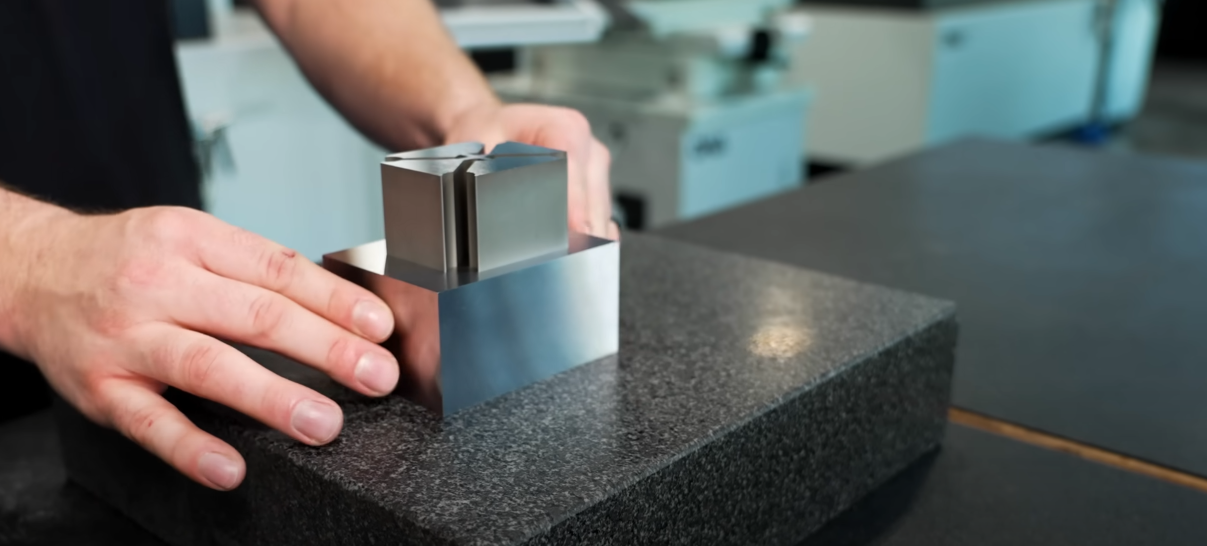

Hooska EDM uses a shaped electrode to create detailed cavities in the material. It’s ideal for creating molds and dies with complex geometries.

Codsiyada iyo Faa'iidooyinka

- Waxaa loo isticmaalaa: Mold cavities, die making, and complex shapes.

- Faa'iidooyinka: Can create deep cavities (up to 200 mm), accuracy of ±0.005 mm.

Dalool qodista EDM

Dalool qodista EDM is used to create tiny holes, often as small as 0.1 mm in diameter, in hard materials. This method is commonly used in the aerospace and medical industries.

Codsiyada iyo Faa'iidooyinka

- Waxaa loo isticmaalaa: Small hole drilling, medical parts, aerospace components.

- Faa'iidooyinka: Drills precise, small holes in tough materials, hole depth-to-diameter ratios up to 100:1.

Simple EDM Types Table

| Type of EDM | Isticmaalka ugu weyn | Faa'iidada Furaha |

|---|---|---|

| Siliga Goynta EDM | Goynta qaababka | High precision (±0.01 mm), can cut thick material (up to 300 mm) |

| Hooska EDM | Creating cavities | Very accurate (±0.005 mm), deep cavities (up to 200 mm) |

| Dalool qodista EDM | Drilling small holes | Precise small holes, high depth-to-diameter ratio (100:1) |

Key Components of EDM Machines

Power Supply and Electrodes

The power supply provides the electrical energy needed for sparking, typically ranging from 50 to 400 volts. The electrodes, made of copper, graphite, or tungsten, conduct the electricity to the workpiece.

Dheecaan Dielectric

The dielectric fluid, usually deionized water or oil, cools the area, controls the spark, and washes away eroded material. The fluid has a breakdown voltage of around 200-400 V, which is crucial for controlled sparking.

Control Systems and Tooling

The control systems manage the movement of the electrode and regulate the spark's energy. Modern EDM machines use CNC controls, which can achieve positioning accuracy of up to ±0.001 mm. Tooling holds the workpiece securely during the machining process.

Simple Components List

| Qeybta | function |

|---|---|

| Power Supply | Provides electrical energy for sparks (50-400V) |

| Electrode | Conducts electricity to the workpiece (Copper , Graphite, Tungsten) |

| Dheecaan Dielectric | Cools, cleans, and controls the spark (200-400V breakdown voltage) |

| Control System | Manages movement and spark control (±0.001 mm accuracy) |

| Qalabaynta | Holds the workpiece in position |

Advantages and Disadvantages of EDM

Faa'iidooyinka Isticmaalka EDM

EDM offers several advantages, particularly in precision machining of complex parts.

Saxnaanta iyo Kakanaanta

- sax: EDM can achieve tolerances as tight as ±0.005 mm.

- Qaababka isku dhafan: EDM can machine intricate shapes and features that are difficult with traditional methods.

Khasaaraha iyo Xaddidaadda

While EDM is powerful, it does have some limitations.

Material Constraints and Speed

- Caqabadaha Alaabta: EDM only works on electrically conductive materials, with a minimum conductivity of 1 x 106 S/m

- Speed: EDM is slower compared to other machining processes, with material removal rates typically around 2-30 mm3/min.

Simple Pros and Cons Table

| Faa'iidooyinka | Qasaarooyinka |

|---|---|

| Saxnaanta Sare (± 0.005 mm) | Limited to conductive materials (>1 x 106 S/m) |

| Qaababka isku dhafan | Slower process (2-30 mm3/ min) |

Primary Applications of EDM Machining

Industries That Benefit from EDM

EDM is widely used in industries requiring high precision and the ability to machine hard materials.

- Hawada hawada: Turbine blades, engine components, typically machined to tolerances within ±0.01 mm.

- Gaadiidka: Mold components, dies, with typical surface finishes of 0.4-0.8 µm Ra.

- Qalabka Caafimaadka: Surgical instruments, implants, requiring high precision (±0.005 mm).

Examples of Products Manufactured Using EDM

| Warshadaha | Tusaalaha Alaabta | Tolerance | Finish dusha |

|---|---|---|---|

| aerospace | Turbine blades, engine parts | ± 0.01 mm | 0.4 µm Ra |

| Automotive | Mold components, dies | ± 0.01 mm | 0.8 µm Ra |

| Caafimaadka | Qalabka qalliinka, maqaar-galaha | ± 0.005 mm | 0.4 µm Ra |

Safety Considerations in EDM Machining

Hab-maamuuska Badbaadada Muhiimka ah

- Xiro Qalabka Ilaalinta: Always use gloves, goggles, and appropriate clothing to protect against sparks and debris.

- Hawo-qaadis habboon: Ensure the machining area is well-ventilated to avoid harmful fumes from the dielectric fluid.

- Dayactirka mashiinka: Regularly check and maintain EDM machines to prevent accidents. Ensure dielectric fluid is replaced every 500 hours of operation.

Common Hazards and How to Mitigate Them

- Khataraha Korontada: Always turn off the machine before performing maintenance or changing electrodes.

- Khatarta Dabka: Keep flammable materials away from the machine and ensure fire extinguishers are available in the workspace.

Comparison with Other Machining Techniques

EDM vs. Traditional Machining

| Aragti | EDM | Mashiin dhaqameed |

|---|---|---|

| sax | ± 0.005 mm | ± 0.02 mm |

| Ku-habboonaanta Shayga | Hard, conductive materials | Most materials, especially metals |

| Xidhashada Qalabka | No direct tool wear | Tools wear out with use |

| Heerka saarista alaabta | 2-30 mm3/ Min | Higher, varies by material and tool |

EDM vs. Laser Cutting

| Aragti | EDM | Laser Cutting |

|---|---|---|

| Ka saarida walxaha | Uses electrical sparks (12,000°C) | Uses a focused laser beam (up to 10,000°C) |

| sax | ± 0.005 mm | ± 0.02 mm |

| Ku-habboonaanta Shayga | Only conductive materials | Conductive and non-conductive materials |

Adeegyada Mashiinka Shiinaha

Injineerinka Saxda ah ee Hal-abuurayaasha

Sawirrada u dir [emailka waa la ilaaliyay]

Dhaqso badan oo jaban

Challenges and Common Problems in EDM Machining

Caqabadaha Farsamada

- Xiro koronto: Electrodes can wear down, affecting precision. This is especially true for copper electrodes used in high-power EDM, where wear can exceed 0.1 mm/hour.

- Xawaaraha socodsiinta oo gaabis ah: EDM is slower compared to other machining processes, with material removal rates typically around 2-30 mm3/min.

Xalka iyo Hababka ugu Fiican

- Use High-Quality Electrodes: High-purity graphite or tungsten electrodes reduce wear and improve precision.

- Hagaaji cabbirada: Adjust voltage (50-400V), current (up to 30A), and spark duration (1-2000 µs) for better efficiency and material removal rates.

How GreatLight Can Help You with Custom EDM Machining Parts

At GreatLight, we specialize in providing high-quality custom EDM parts. Our advanced machines and skilled technicians ensure that every part meets your exact specifications. Whether you need complex shapes or hard materials machined, GreatLight has the expertise to deliver precision and quality.

Waa maxay sababta aad u dooratay Great Light?

- Khabiirro: Over 15 years of experience in EDM machining.

- Tayada: We use state-of-the-art equipment like Sodick AG40L and Mitsubishi EA28V, ensuring precision up to ±0.002 mm.

- Adeegga: Dedicated support and custom solutions tailored to your needs.

Contact GreatLight China today to learn how we can help with your EDM machining requirements!

Tel/WeChat:

Tel/WeChat:  E-mail:

E-mail:

Bogga Hore

Bogga Hore

Qaybaha Mashiinka CNC ee Khafiifka ah ee Hawada Sare: Dhaqamada iyo Farsamooyinka ugu Fiican

Qaybaha Mashiinka CNC ee Khafiifka ah ee Hawada Sare: Dhaqamada iyo Farsamooyinka ugu Fiican