01

kenyelletso

Joalo ka sesebelisoa se tsoetseng pele sa ts'ebetso, laser e bapala karolo ea bohlokoa le ho feta lefapheng la welding ea indasteri. Leha thekenoloji ea khale ea welding ea laser e ka laola liphoso tsena ho isa bohōleng bo itseng, phello ea eona hangata e lekanyetsoa ke litekanyetso le lits'ebetso tse tsitsitseng. Lilemong tsa morao tjena, ho hlaha ha thekenoloji ea ho tjheseletsa laser swing ho tlisitse tharollo e ncha bakeng sa ho laola sekoli. Ka ho hlahisa laser beam oscillation nakong ea ts'ebetso ea welding, theknoloji ena e ka ntlafatsa haholo matla a letamo la weld, ka ho etsa joalo e ntlafatsa boleng ba weld. Thekenoloji ea swing laser welding e thehiloe haholo holima taolo e nepahetseng le thekenoloji ea swing ea beam ea laser ho fihlela welding e sebetsang hantle le ea boleng bo holimo. Ts'ebeliso ea theknoloji ea welding ea laser e ka etsa hore welding ea laser e sebelisoe haholo. Bakeng sa likarolo tse kholoanyane le likarolo tse nang le li-weld seams tse pharaletseng, li-welding tsa laser tse sebetsang hantle le tse nepahetseng li ka finyelloa, ke hore, mokhoa oa motheo le ho nepahala ha kopano ea sehlahisoa li phutholohile.

02

Tlhaloso ea laser swing welding

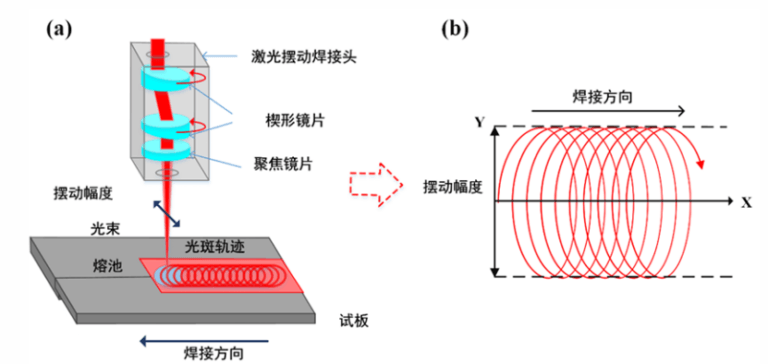

Nakong ea ts'ebetso ea ho cheselletsa, lebone la laser le reretsoe kapele le ka nepo ho koahela sebaka sohle sa welding. Ha sefate se tsamaea ka tsela ea weld, e oscillates ka nako e le 'ngoe ka libopeho tse sa tšoaneng tse kang chitja, setšoantšo sa 8 le spiral, joalokaha ho bontšitsoe setšoantšong sa 1. Oscillation ena ha e finyelle feela ho futhumala ha junifomo, empa hape e fokotsa ka katleho liphoso tse kang li-vents le mapetsong.

Setšoantšo sa 1. Setšoantšo sa moralo oa mokhoa oa ho tjheseletsa oa laser oscillation.

(a) Laser welding e nang le hlooho ea welding ea IPG D50,

(b) Tsela ea sebaka sa leseli ka mokhoa oa circular oscillation.

03

Litšobotsi tsa laser swing welding

Ka ntshetsopele ya theknoloji, oscillating laser tjheseletsa thekenoloji e boetse e thakgola mefuta e fapaneng ya mefuta ho ea ka mesebetsi le litlhoko, ho akarelletsa le laser galvanometer scanning lihlooho, tjheseletsa oscillating lihlooho, joalo-joalo, ho ikamahanya le litlhoko tsa tjheseletsa tsa liindasteri tse fapaneng. Ho potoloha beam ka hlooho ea welding ea laser-specific pivoting ha e holise feela mofuta oa ts'ebetso, empa hape ho eketsa mamello ea bophara ba weld, ka hona ho ntlafatsa boleng ba weld. Swing laser welding e na le litšobotsi tse latelang:

(1) Phepelo e tšoanang ea mocheso: Spin welding e ka fihlela mocheso o ts'oanang oa weld ka ho fetola boemo ba mohloli oa mocheso oa welding le ho qoba bothata ba khatello ea khatello ea mocheso nakong ea ts'ebetso ea welding.

(2) Boleng bo phahameng ba weld: Ka ho kenya mocheso o ts'oanang, oscillation welding e ka fihlella boleng bo bongata bo ts'oanang le bo tsitsitseng le ho fokotsa ho hlaha ha liphoso tsa welding.

3

Ntlafatsa ts'ebetso ea tlhahiso: Swing welding e ka fokotsa deformation ea welding le ho fokotsa khatello ea masala ea welding, ka hona ho ntlafatsa katleho ea tlhahiso le boleng ba welding.

(4) Taolo e matla: Boholo bo boholo ba ntlha ea swing bo thusa ho koala likheo tse kholoanyane. The amplitude, frequency le lebelo la swing welding ka laoloa ka nepo ho fihlela litlhoko tse fapaneng tsa tjheseletsa le litlhoko tsa workpiece.

Setšoantšo sa 2. (a) Mefuta ea mekhoa ea oscillation e sebelisoang ka laser oscillation welding: circular, infinite, figure 8, transverse le sinusoidal (b) Lisebelisoa tsa laser oscillation welding liindasteri tse fapaneng;

04

Molao-motheo oa ts'ebetsong ea swing laser welding

Laser oscillation e finyelloa haholo ka ho tjheseletsa manonyeletso. Hona joale, ho na le mefuta e 'meli ea ho tjheseletsa manonyeletso, e leng galvanometric welding joints le swivel welding joints.

Khokahano ea solder ea Galvanometer:

Likarolo tse ka sehloohong tsa lenonyeletso la galvanometer ke collimator ea ho atolosa, lense e tsepamisitseng maikutlo, XY dual-axis scanning galvanometer, boto ea taolo le sistimi e amohelang software ea komporo. Galvanometer e ka fetola tsela eo lebone la laser le eang ka eona, ea khanna oscillation ka mochini oa motlakase oa motlakase, kapa ea khanna sekhechana sa ho potoloha ka mochini oa stepper. Ka ho sisinyeha ha galvanometer, lebone le ka hlahlojoa ka potlako, sebaka se khanyang se ka laoloa ho tsamaea ka lebelo le phahameng holim'a weld, 'me ho ka fumanoa weld e loketseng. Beam e kena ka har'a mochine oa collimation ho tloha QBH, e fetoha lesela le ts'oanang, ebe e tsepamisitsoe ke mojule oa ho tsepamisa maikutlo ho lokisa tšitiso ea pincushion ea lebone la laser holim'a sefofane se shebaneng le ho etsa bonnete ba hore motsamao o nepahetseng oa sefate o le sefofaneng se le seng. . Hajoale, oscillation ea beam e fihlelleha haholo ka li-galvanometers tse khonang ho mamella li-laser tse matla, joalo ka ha ho bonts'itsoe ho Setšoantšo sa 3.

Setšoantšo sa 3. (a) Molao-motheo oa laser oscillating; (b) Setšoantšo sa sebele sa ho tjheseletsa se kopantsoeng ka galvanometer ea matla a phahameng.

Li-galvanometer li arotsoe ka 2D le 3D galvanometers. Li-galvanometers tsa 2D li ka laola laser ho trajectory efe kapa efe ea mahlakore a mabeli, 'me li-galvanometer tsa 3D li ka laola laser ka lifofane tsa XYZ, ntle le ho tsamaisa lifofane tse letšehali le tse nepahetseng, li ka boela tsa fetoloa ka bophahamo. Ha ho bapisoa le 2D galvanometer, sebopeho sa 3D galvanometer haholo-holo e eketsa "Z-axis optical system", e le hore galvanometer ea 3D e ka fetola ka bolokolohi boemo ba ho tsepamisa maikutlo nakong ea ts'ebetso ea ho tjheseletsa le ho etsa holim'a tjheseletsa sebakeng se kobehileng, ntle le tlhokahalo ea ho fetoha. tšehetso e joalo ka sesebelisoa sa mochini, joalo-joalo joalo ka galvanometer ea 2D. Bophahamo ba roboto bo sebelisetsoa ho lokisa boemo ba sebaka sa welding. Motsoako oa solder oa galvanometer o khelosoa ke enjene e nang le lense. Motlakase o tsamaisoa ke motlakase o itseng 'me o na le melemo ea ho nepahala ho phahameng, inertia e tlaase le karabelo e potlakileng.

Setšoantšo sa 4. Molao-motheo oa ho sebetsa oa 3D galvanometer welding joint.

Hlooho ea tjheseletsa e Swivel:

Manonyeletso a tjheseletsang oscillating hangata a na le lisebelisoa tsa taolo tse nepahetseng haholo tse ka laolang ka nepo tsela ea oscillation le lebelo la lebone la laser. Mokhoa ona o entsoe haholo ka mochine oa ho hlahloba (motlakase, lense), mochine o lebisang tlhokomelo ea collimation le tsamaiso ea taolo (boto ea taolo ea ts'ebetso), joalokaha ho bontšitsoe setšoantšong sa 5. Lebone la laser le qala ho tsamaisoa ka mochine oa ho hlahloba o entsoeng ka liipone tse peli tseo oscillation ea tsona e laoloang ke servomotor e thata haholo. Mojule oa ho tsepamisa mohopolo oa collimation o sebelisetsoa ho lokisa lebone la laser hore le be lebaleng le ts'oanang le ho le tsepamisa ka mojule oa ho tsepamisa maikutlo ho netefatsa hore sebaka se tsepamisitsoeng sa leballo sebakeng sa welding se nepahetse. Beam e ka tsamaea haufi le lilepe tsa X le Y. Ntle le moo, hlooho ea swing welding e ka ba le lisebelisoa tse tlatsitsoeng ka terata le ts'ebetso e tobileng ea ho sireletsa khase ho ntlafatsa boleng le ts'ebetso ea welding.

Setšoantšo sa 5. Sets'oants'o sa moralo oa motsoako oa swivel welding.

05

ha re phethela

Manonyeletso a swivel welding a sebelisoa haholo tlhahisong ea likoloi, sefofane, tlhahiso ea elektroniki le masimo a mang ka lebaka la litlamorao tsa ona tse sebetsang hantle le tsa boleng bo holimo. Hlooho ea swivel welding e na le melemo ea eona e ikhethang, haholo-holo ha likarolo tse nang le libopeho tse rarahaneng kapa litlhoko tse phahameng tse nepahetseng li hloka ho ts'oaroa.

Theknoloji ena ha e ntlafatse ts'ebetso ea manonyeletso a cheselitsoeng feela, empa hape e holisa sebaka sa ts'ebeliso ea welding ea laser ha ho etsoa tlhahiso e nepahetseng. Le hoja welding ea laser oscillation e na le bokhoni bo boholo, ho hlokahala lipatlisiso tse tebileng mabapi le tšusumetso ea mekhoa ea ho sebetsa nakong ea laser oscillation welding. Re tla arolelana tsebo ea rona e khethehileng mabapi le liparamente tsa ts'ebetso ea laser swing welding le phello ea tsona ho bofokoli ba weld ho latela.

Daguang e tsepamisitse maikutlo ho faneng ka litharollo tse kang lits'ebeletso tsa machining tsa CNC tse nepahetseng (3-axis, 4-axis, 5-axis machining), CNC milling, khatiso ea 3D le lits'ebeletso tsa prototyping tse potlakileng.